- P

- M

- K

- N

KGZ

Features

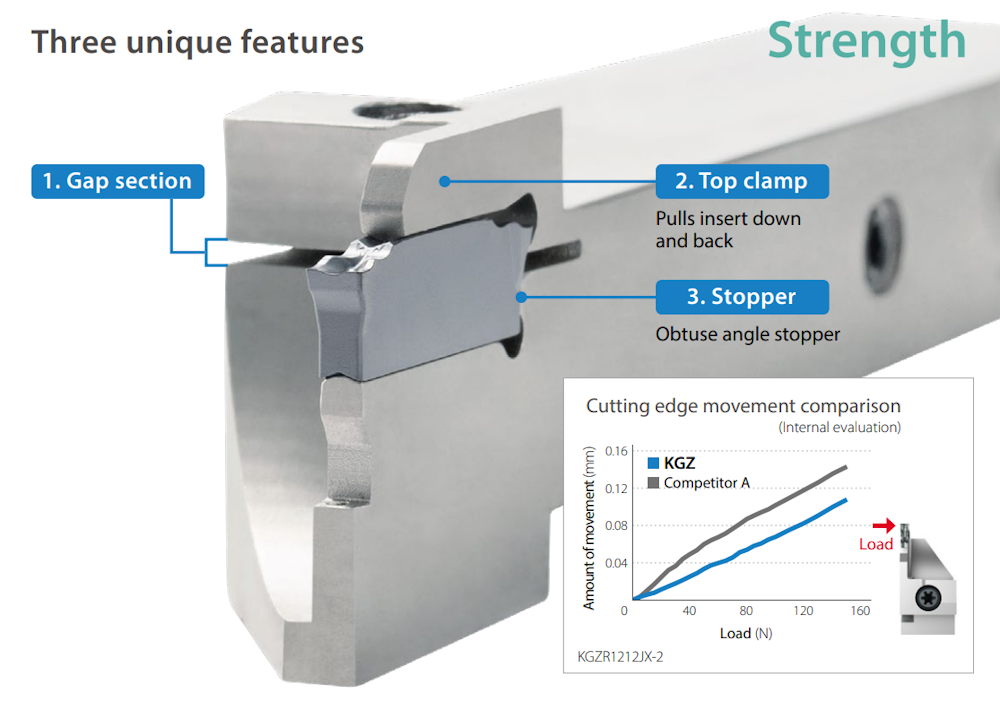

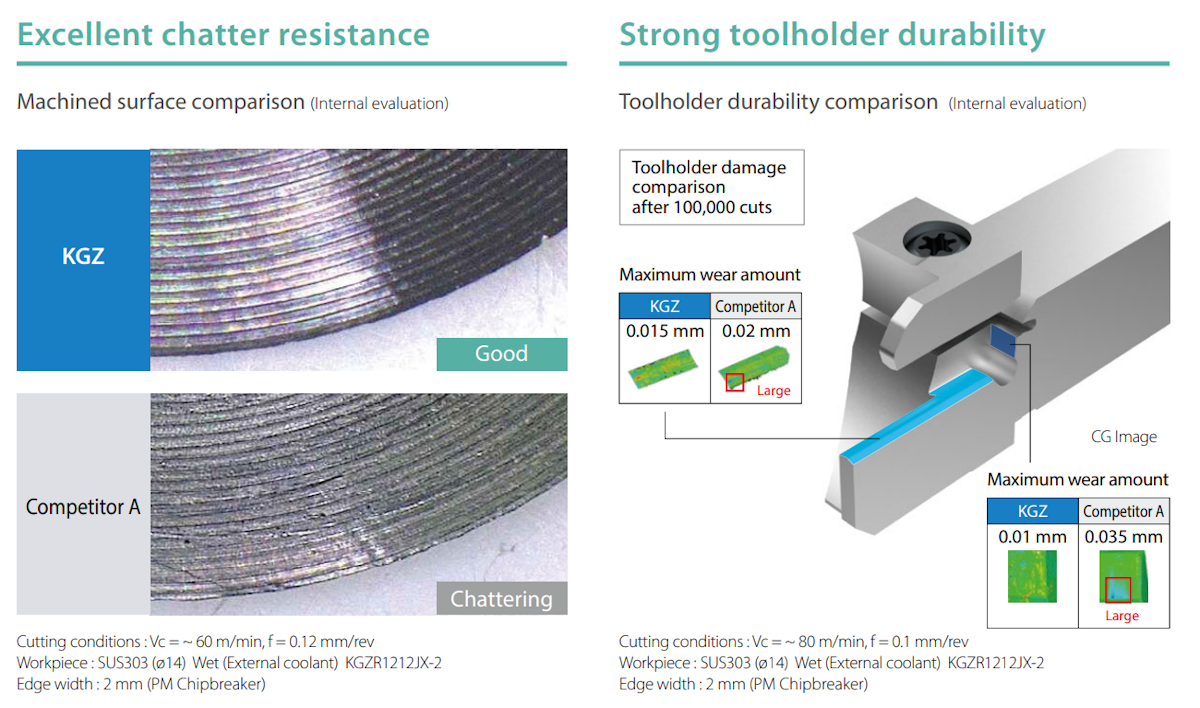

Strong clamping ensures stable machining.

Inserts are firmly clamped with a newly developed special clamp. Suppresses chattering to achieve a stable finishing surface quality.

Strong resistance to machining loads improves toolholder durability and allows for high-efficiency machining.

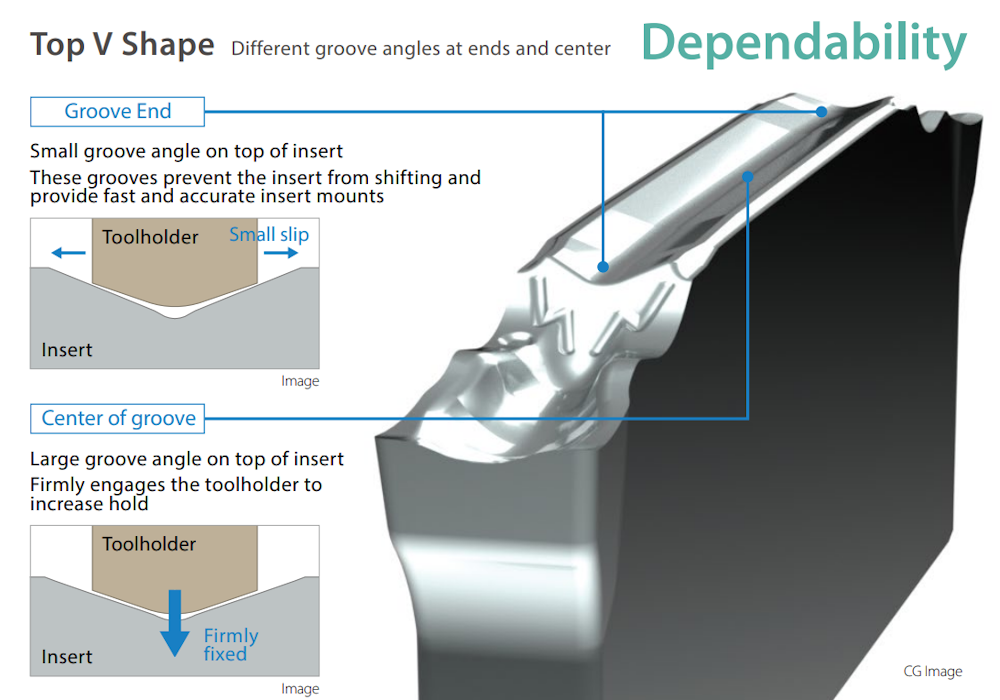

Excellent workability; smooth and secure insert mounting.

Optimizing the groove angle on the insert's top surface ensures smooth and secure mounting. With small angles at both ends of the groove, the insert is less likely to shift sideways during mounting, allowing for smooth installation. In addition, the larger angle at the center of the groove allows the toolholder and the insert to mesh firmly, improving the clamping force.

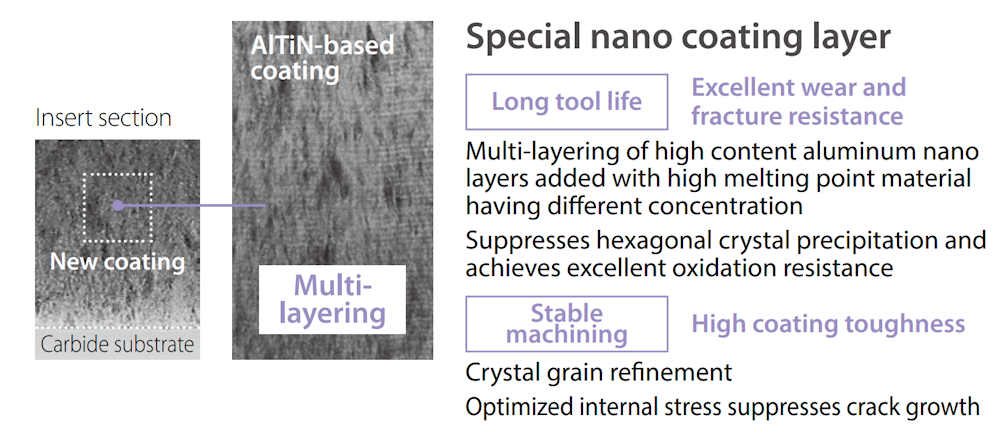

New PR20 series. MEGACOAT NANO EX for long tool life

MEGACOAT NANO EX, a PVD coating specialized for grooving and cut off, achieves long tool life and stable machining.

Utilizes a proprietary nano-laminated coating with a high-content aluminum (Al) layer, achieving both excellent wear and fracture resistance.

PR2015: Primary recommendation for cast iron

PR2025: Primary recommendation for steel

PR2035: Primary recommendation for stainless steel

Case Study

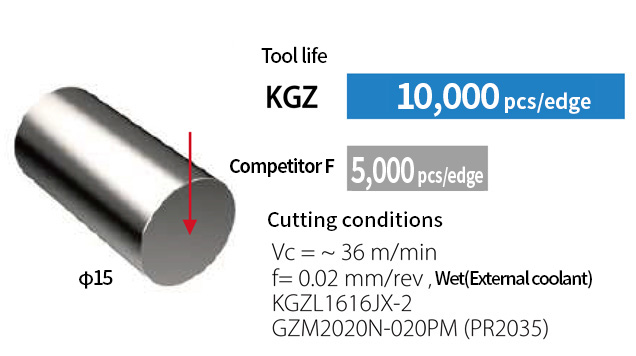

Pin SUS304

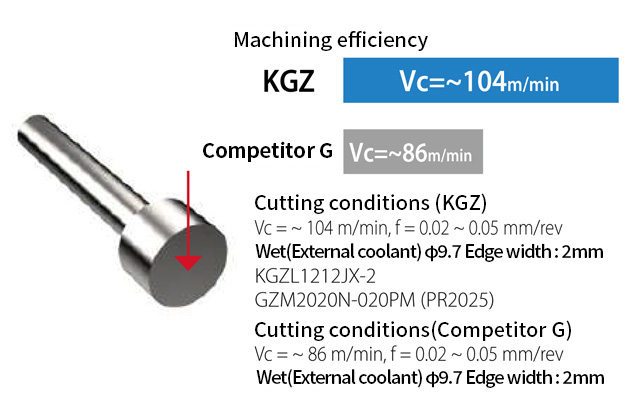

Base metal (core) S45C

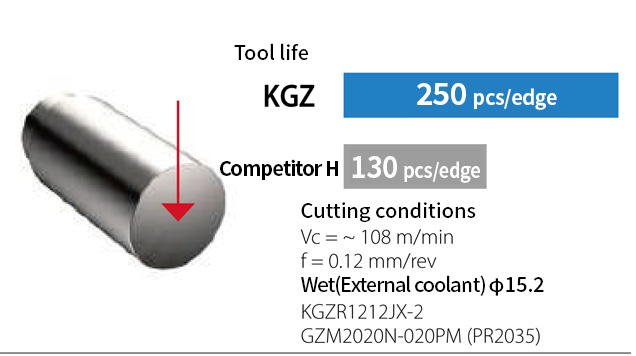

Automotive parts SUS304F

Lineup

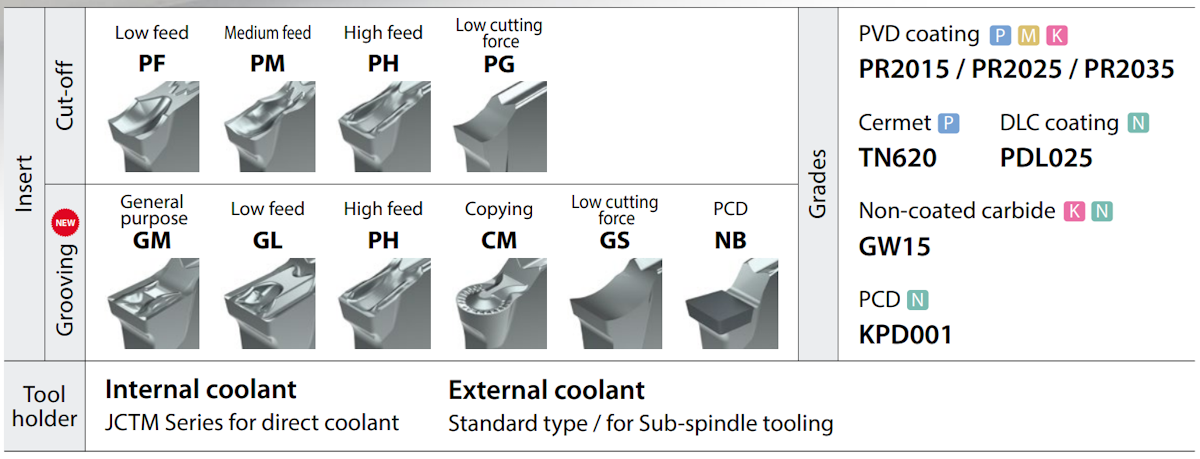

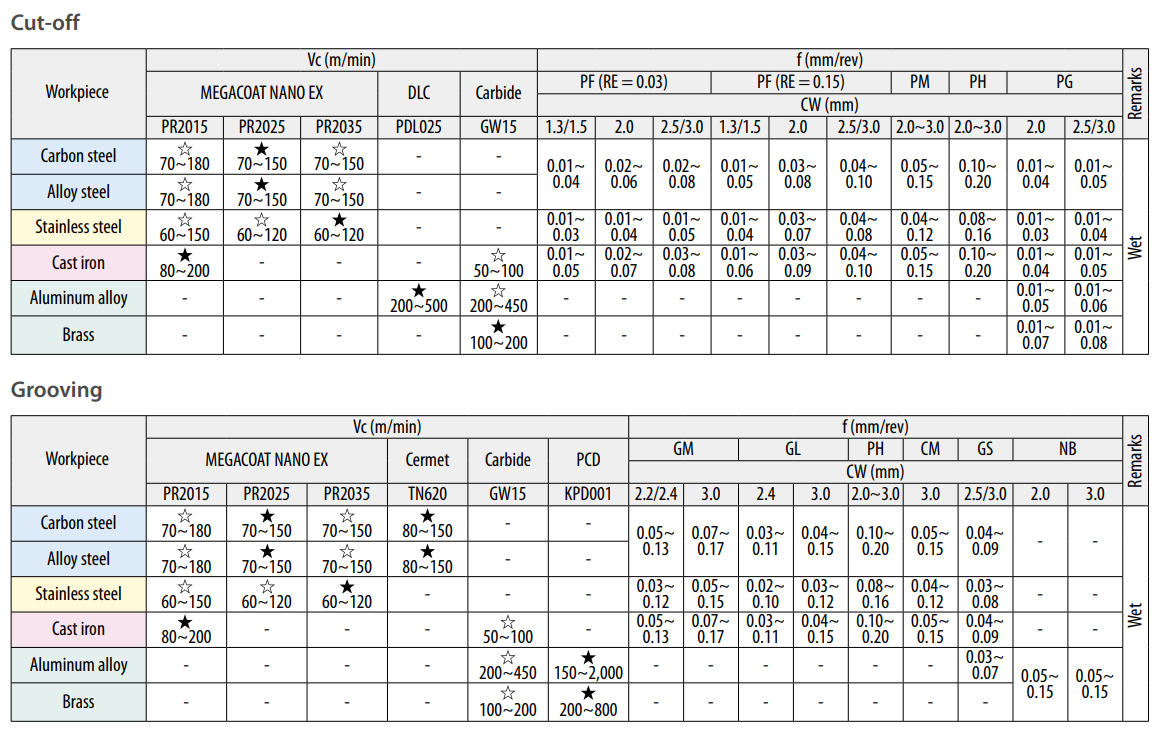

Cut off inserts: Low feed PF / Medium feed PM / High feed PH / Low Cutting Force PG

Grooving inserts: General Purpose GM / Low feed GL / High feed PH / Profiling CM / Low Cutting Force GS / PCD NB

Toolholder: Internal coolant compatible JCTM series / Standard type / Sub-spindle compatible type

Recommended cutting conditions

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)