- H

KBN015

Features

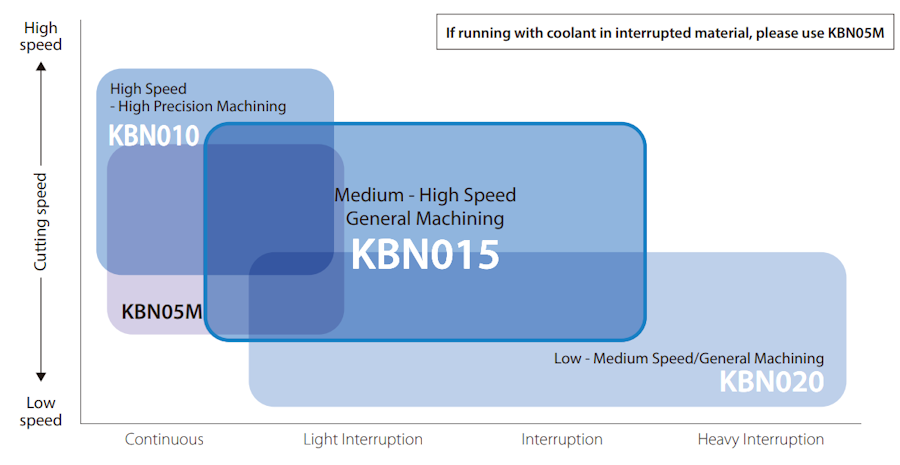

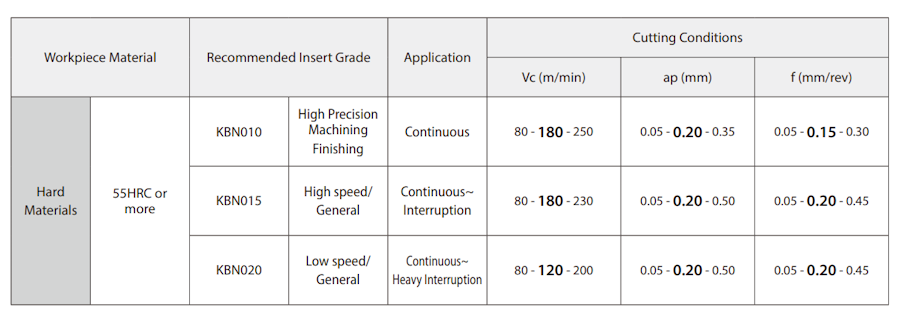

Three grades for a variety of hardened material applications.

KBN015: Primary recommendation for general purpose. Applicable to a wide range of cutting applications, from continuous to interrupted and high-speed machining.

KBN010: Catering to high-speed and high-precision machining. Superior surface finish

KBN020: Suitable for Heavy interrupted machining. High Fracture resistance

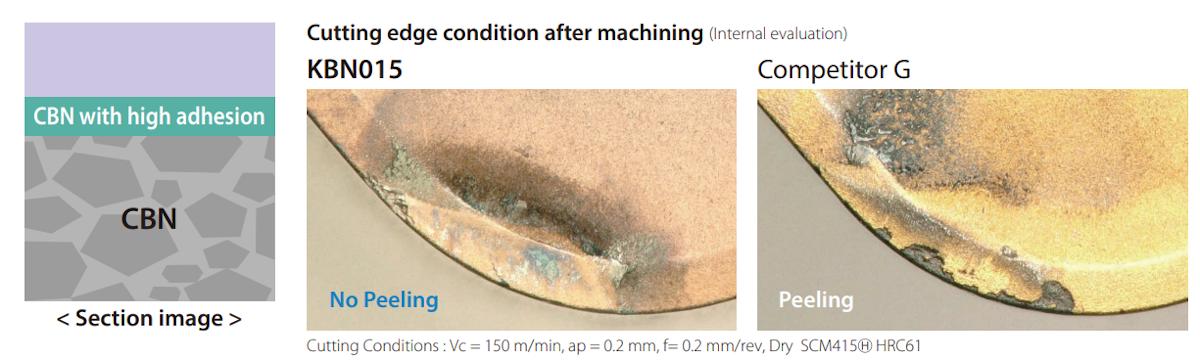

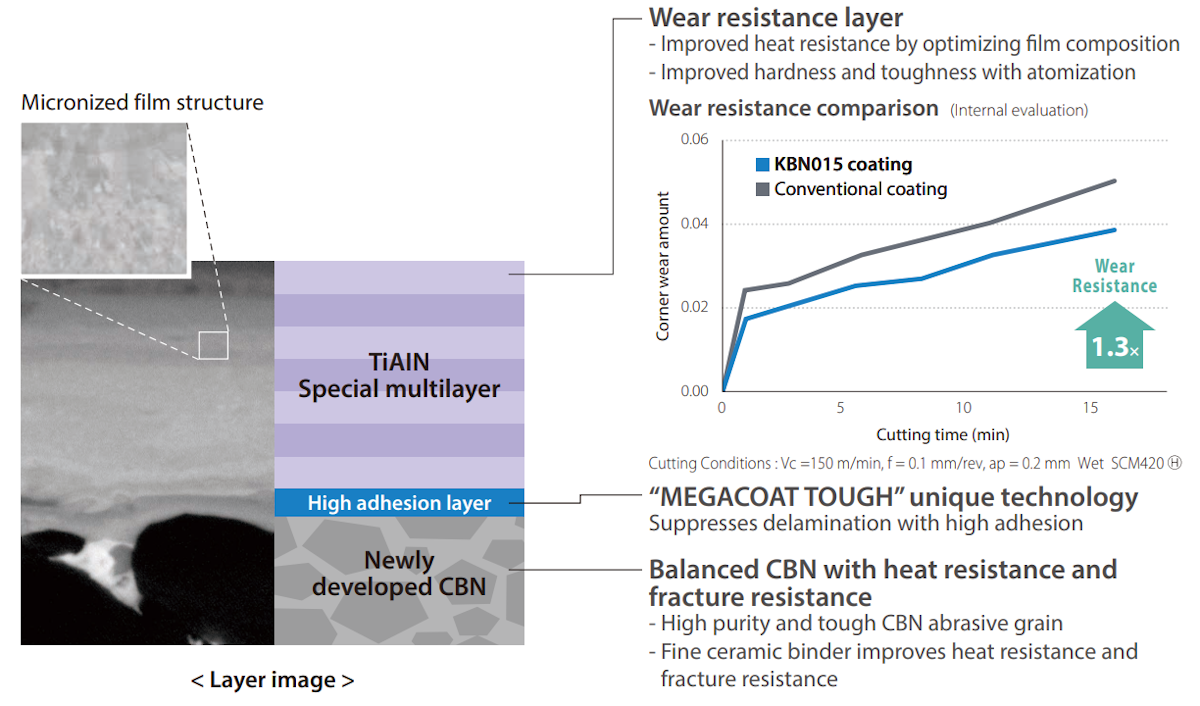

Long tool life with our unique coating "MEGACOAT TOUGH" and new CBN

The newly developed "MEGACOAT TOUGH" coating with a highly adhesive layer made specifically for CBN is used. The high adhesive strength prevents film peeling, achieving long tool life and stable machining.

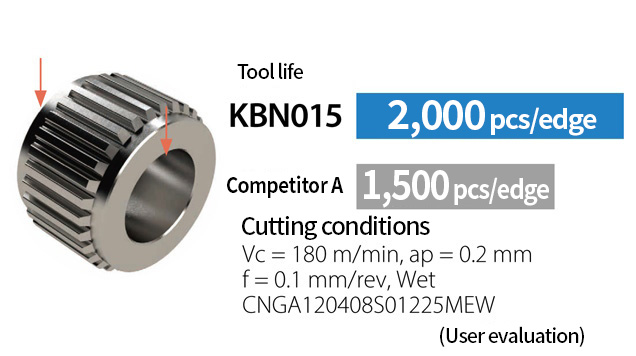

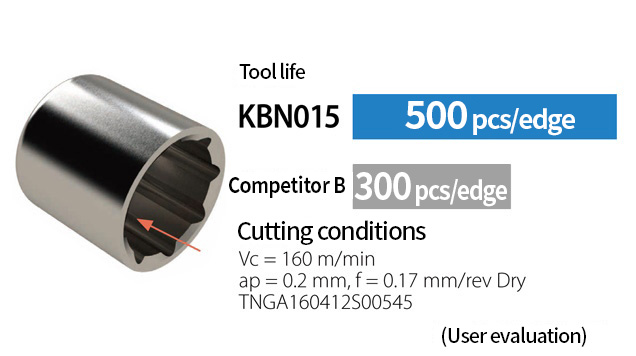

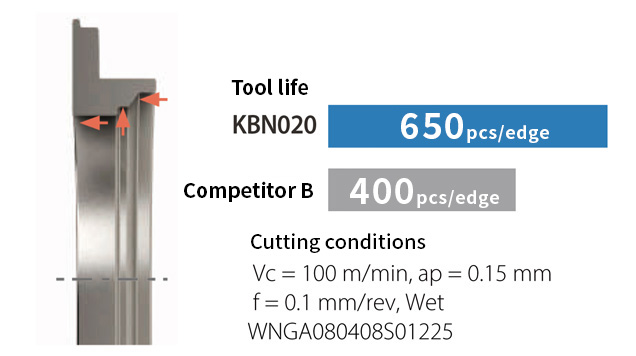

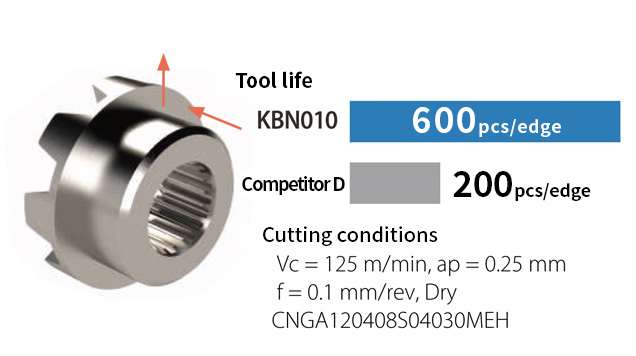

Case Study

Gear SCM420H 58-60HRC

Outer race S55C 62HRC

Clutch SCr420H

Gear SNCM220Ⓗ 58HRC

Lineup

KBN010: High speed/high precision machining

KBN015: Medium to high speed / Primary recommendation for General Purpose

KBN020: Low to medium speed / For general Purpose

Recommended cutting conditions

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)