- P

- M

- K

Highly efficient modular drill

DRA

General info.

General info.

Machining video

Features

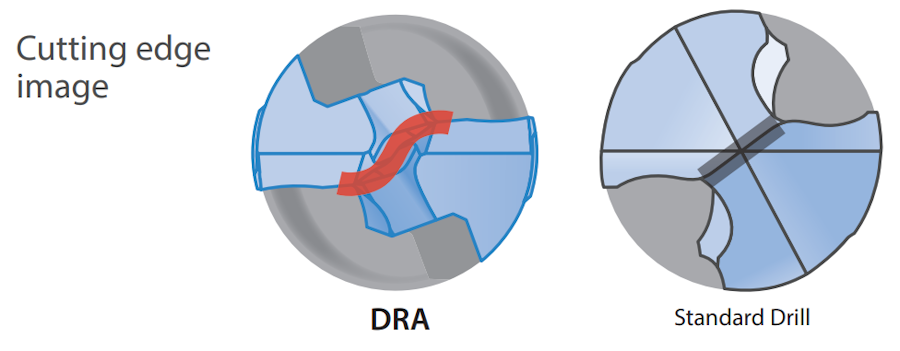

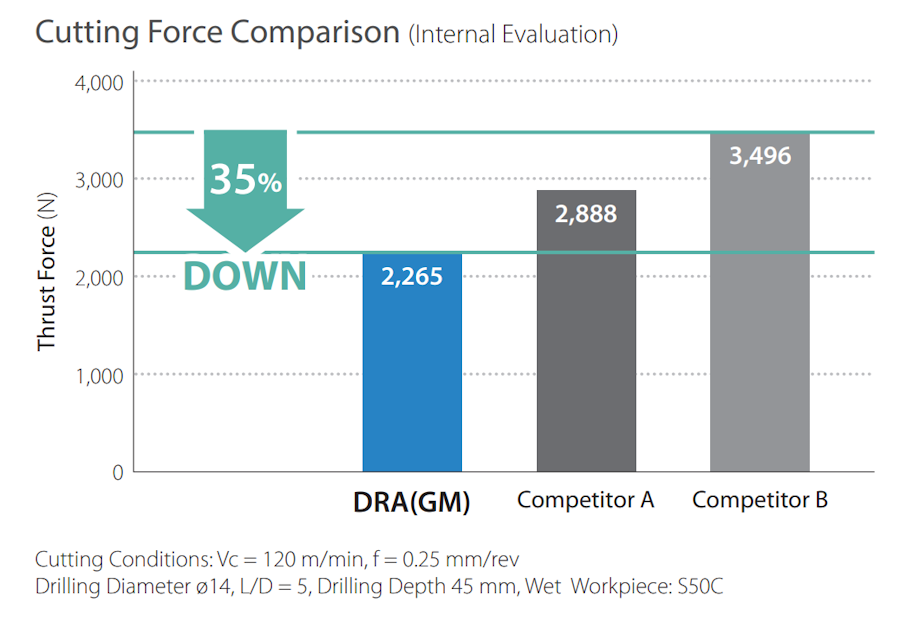

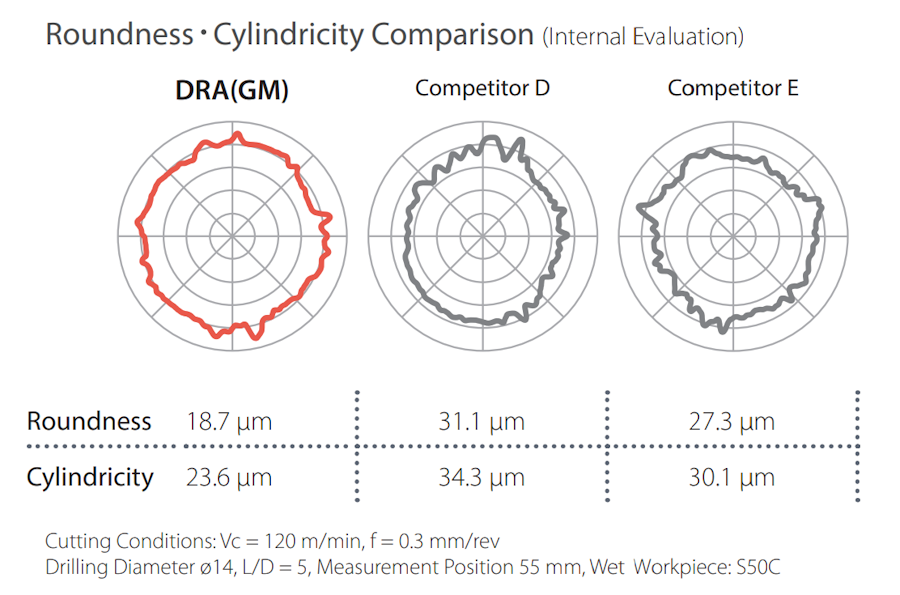

Low Cutting Force design achieves excellent hole accuracy

The S-shaped curved cutting edge with a special chisel shape reduces thrust force and suppresses vibration during workpiece engagement.

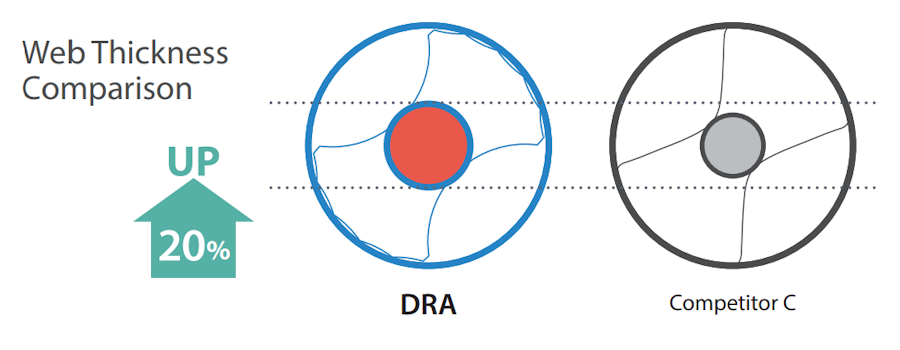

Large web thickness prevents deflection

By ensuring a large web thickness for the toolholder, deflection is suppressed and hole diameter accuracy is improved.

Case Study

Attachment SS40

While competitor J's product required inching due to chip clogging, the DRA has good chip evacuation even without it.

(Customer evaluation)

(Customer evaluation)

Plate SUS304

DRA has a 5 times longer Tool life than competitor K wirh less cutting noise.

The finished surface was also good, enabling stable machining.

(Customer evaluation)

The finished surface was also good, enabling stable machining.

(Customer evaluation)

Lineup

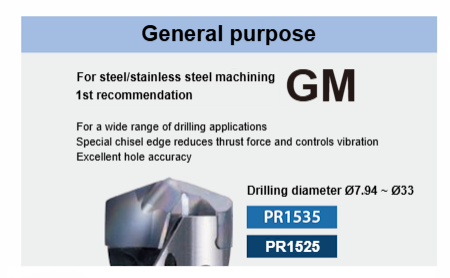

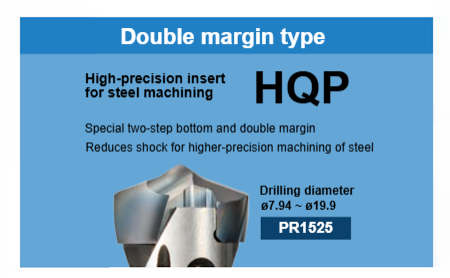

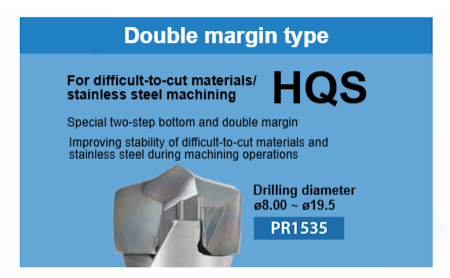

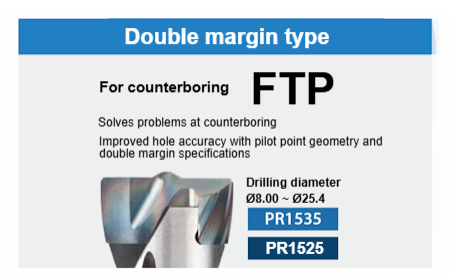

Four types of drill heads to suit various applications.

Primary recommendation for steel and stainless steel machining: General-purpose GM

Double margin type for high-precision steel machining: HQP / For difficult-to-cut materials and stainless steel machining: HQS

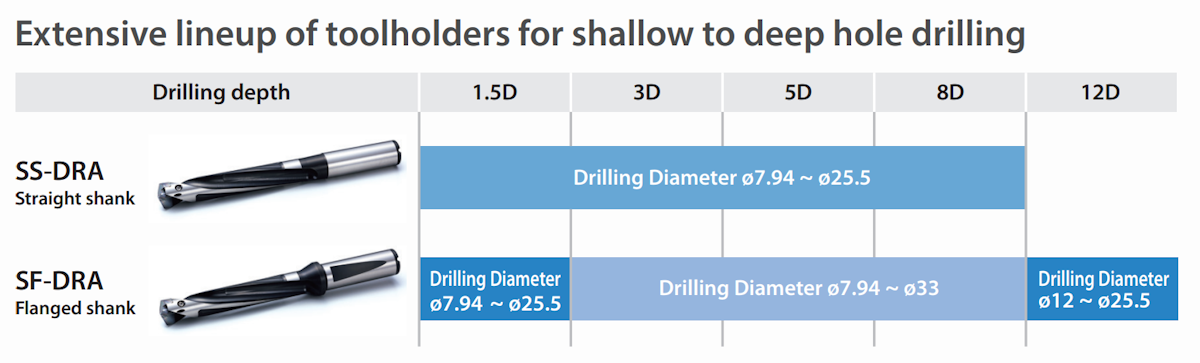

A wide variety of toolholder options are available. From shallow to deep holes.

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)