- P

- M

- K

KDA Mini

Features

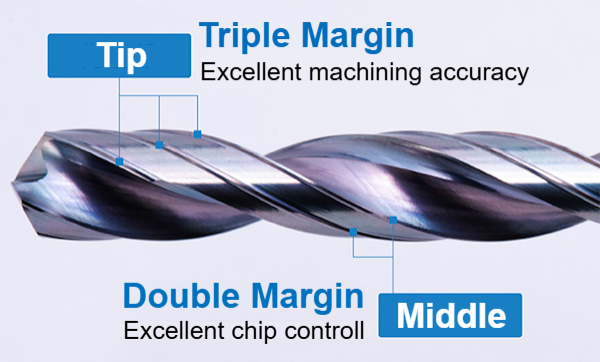

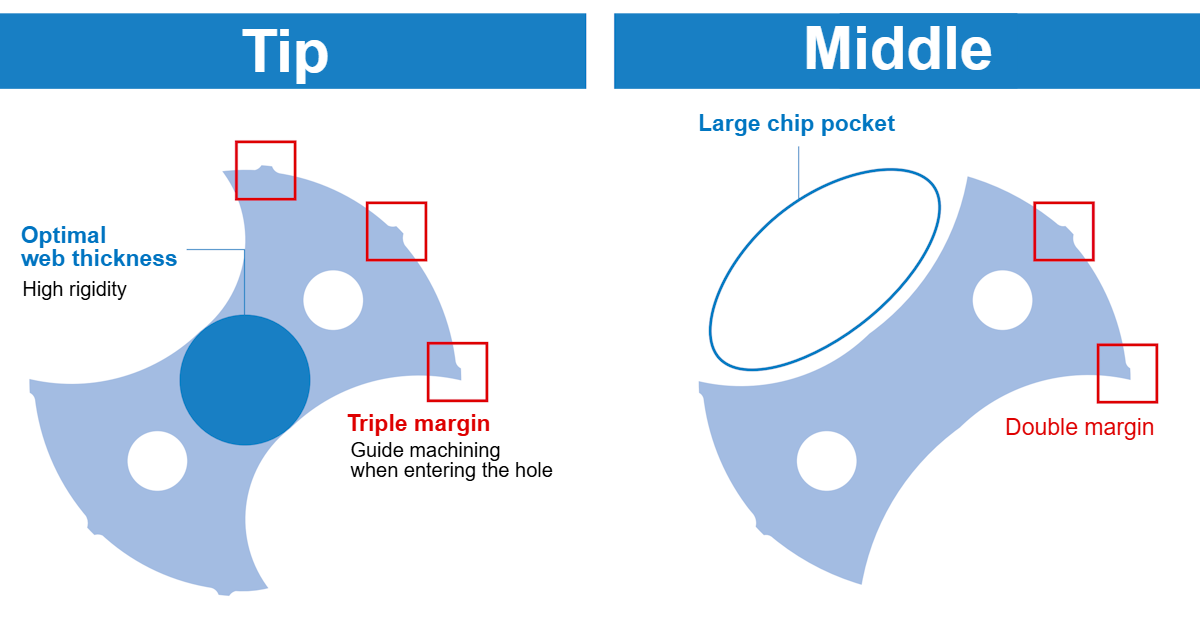

New concept "Triple & Double Margin*" realizes high precision and stable machining

The margin geometry at the end and middle of the drill is optimized to achieve high-precision, stable drilling.

End portion has triple margins. Three sets of margins guide the cutting at the entry point, improving cutting accuracy.

The middle section has a double margin, ensuring ample space for chip evacuation and reducing chip problems.

* Type C (with coolant hole) only

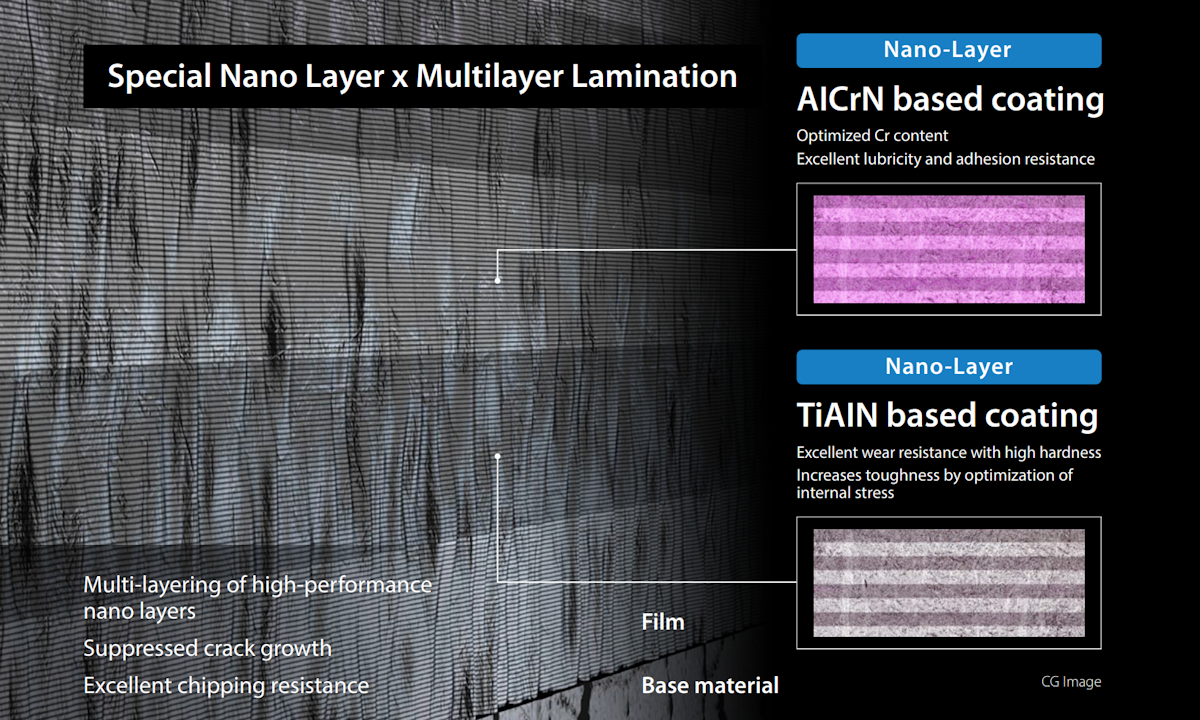

New coating MEGACOAT NANO EX for long tool life

The newly developed proprietary coating MEGACOAT NANO EX achieves long tool life. "Double lamination technology" that laminates two types of special nano-layers in multiple layers achieves high levels of wear, welding and chipping resistance.

Case Study

Machine parts SUS316L

(Customer evaluation)

Machine parts SUS304

(Customer evaluation)

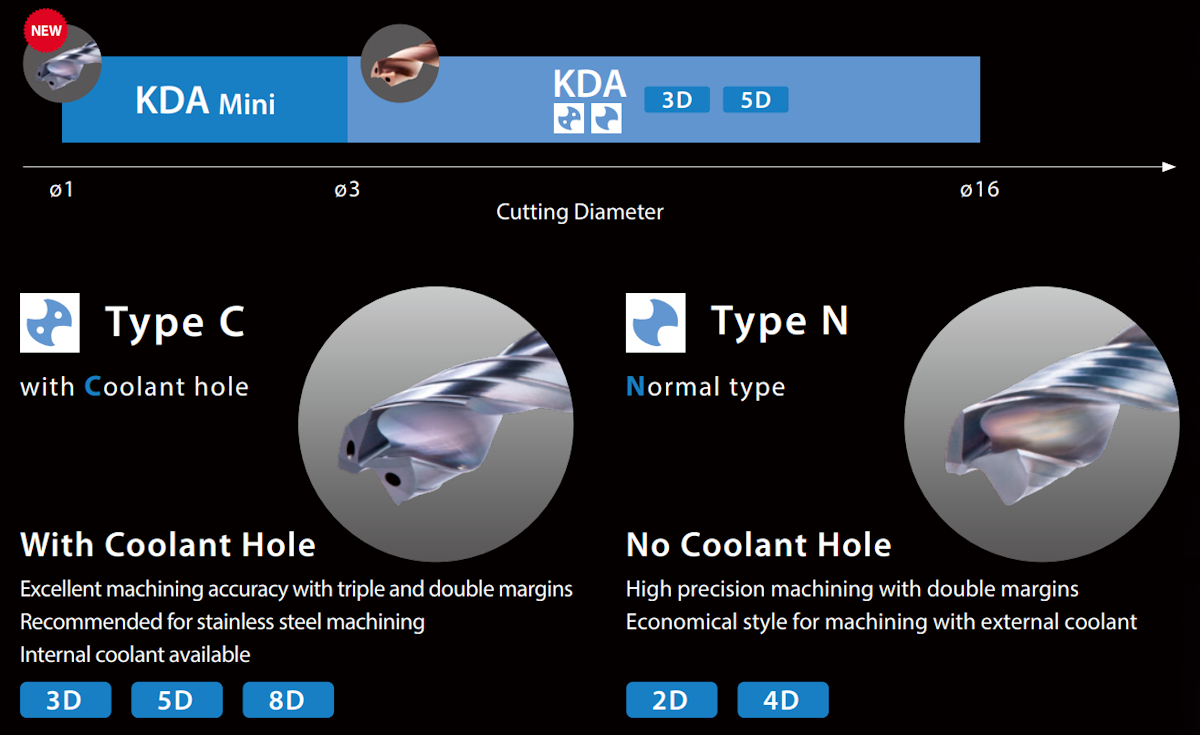

Lineup

φ1.0 ~ φ2.9

Type C (with coolant hole): 3D / 5D / 8D

Type N (without coolant hole): 2D / 4D

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)