- P

- M

- K

High-efficiency coated solid carbide drill

KDA

General info.

Features

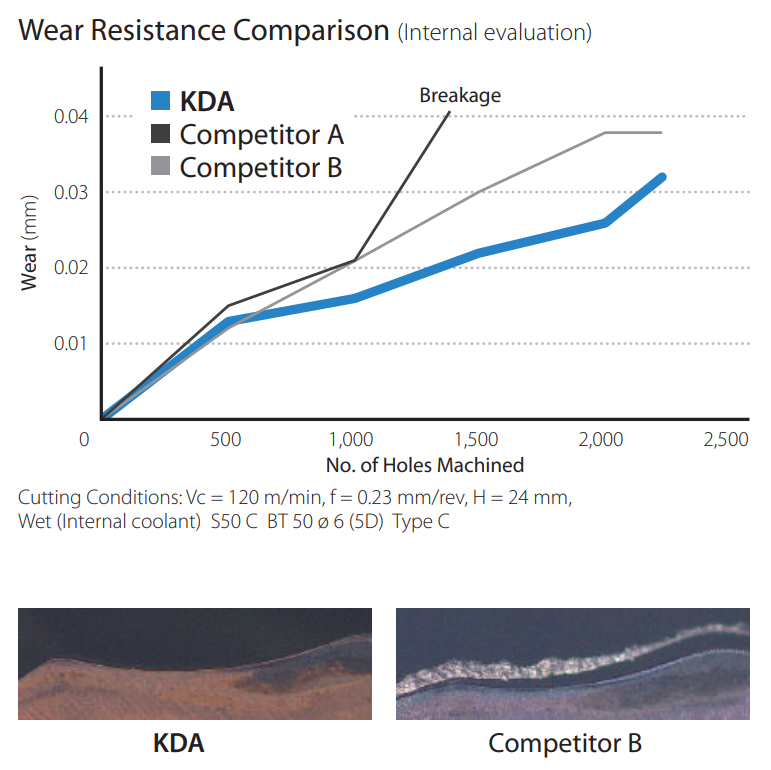

High-performance coating that achieves long tool life

Adopts an aluminum chromium (AlCr) based coating with excellent wear and heat resistance.

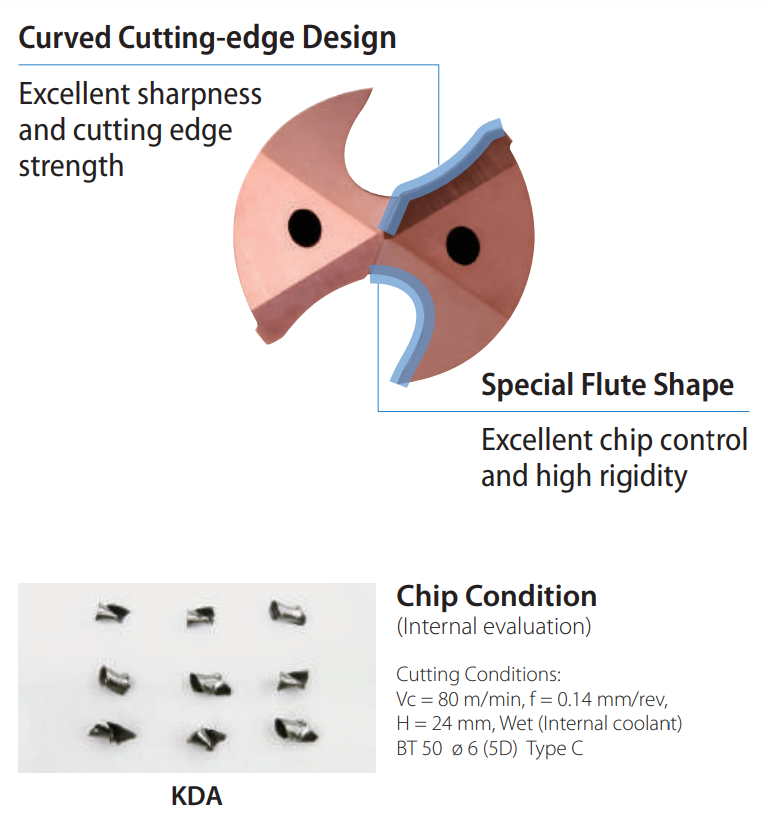

Unique geometry realizes stable machining

Wave-design cutting edge and unique flute geometry

Case Study

Body SCM440 ø6.9 (5D) drilling

Even when its tool life was extended by 20% beyond the current setting of competitor's, KDA showed less shoulder wear and remained in good cutting edge condition. (Customer evaluation)

Mold parts Cold tool steel ø5.1 (3D) drilling

KDA has smaller variation in hole diameter compared to competitor's products, achieving high-precision machining.

The machining noise was quiet and the chip condition was good.

(Customer evaluation)

The machining noise was quiet and the chip condition was good.

(Customer evaluation)

Nozzle SUS304 ø5.5 (3D) drilling (finished to ø6.0 in post-process)

KDA achieves stable machining of stainless steel and 2.3 times Tool life

Competitor's product was unstable due to Sudden fracture.

(Custome revaluation)

Competitor's product was unstable due to Sudden fracture.

(Custome revaluation)

Shaft SUS630 ø5.1 (3D) drilling

KDA achieves stable machining and 1.2 times Tool life

Competitor's products are unstable, so two tools are required for one work lot.

KDA was able to handle it with just one.

(Customer evaluation)

Competitor's products are unstable, so two tools are required for one work lot.

KDA was able to handle it with just one.

(Customer evaluation)

Lineup

A design and product lineup that pursue versatility to support a wide range of machining applications.

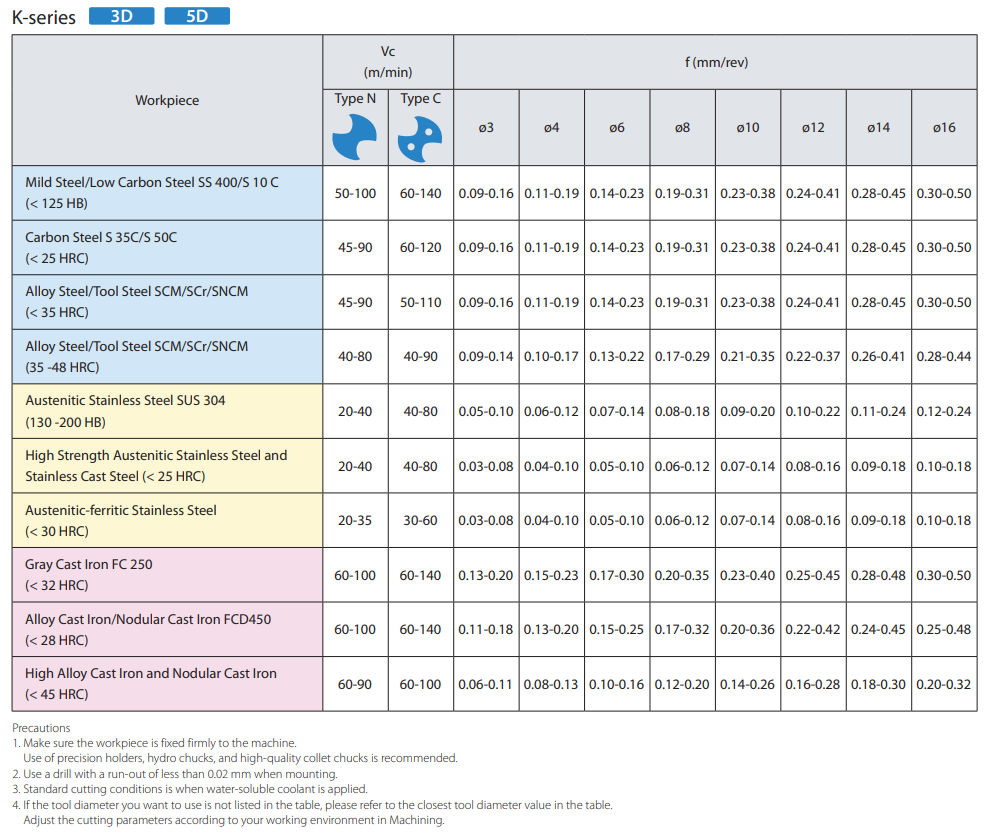

Recommended cutting conditions

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)