- P

- M

- K

- S

MFH Series

Features

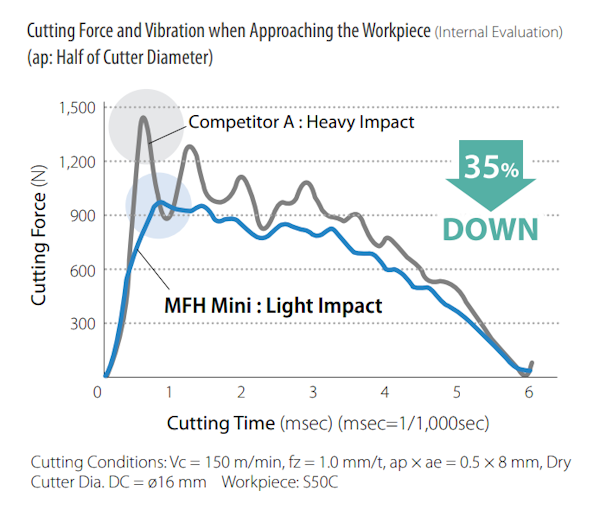

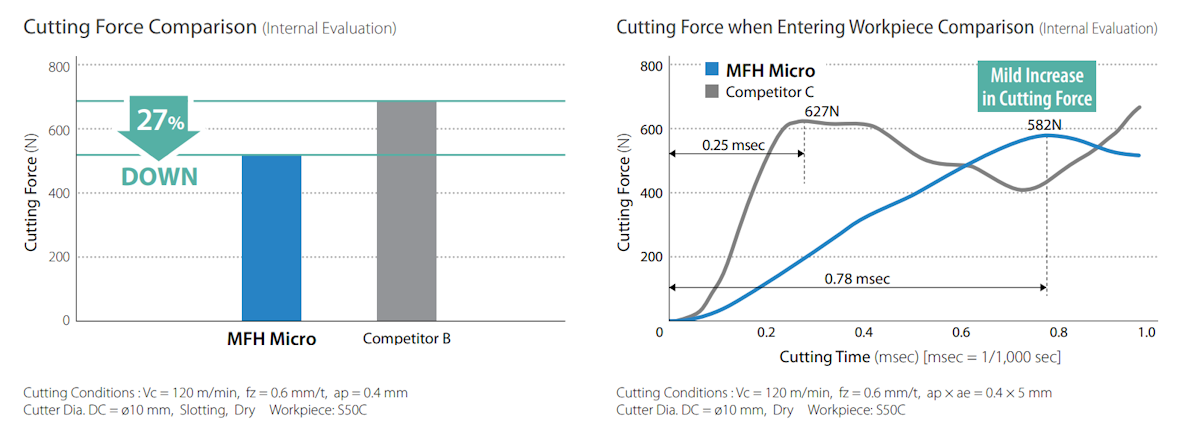

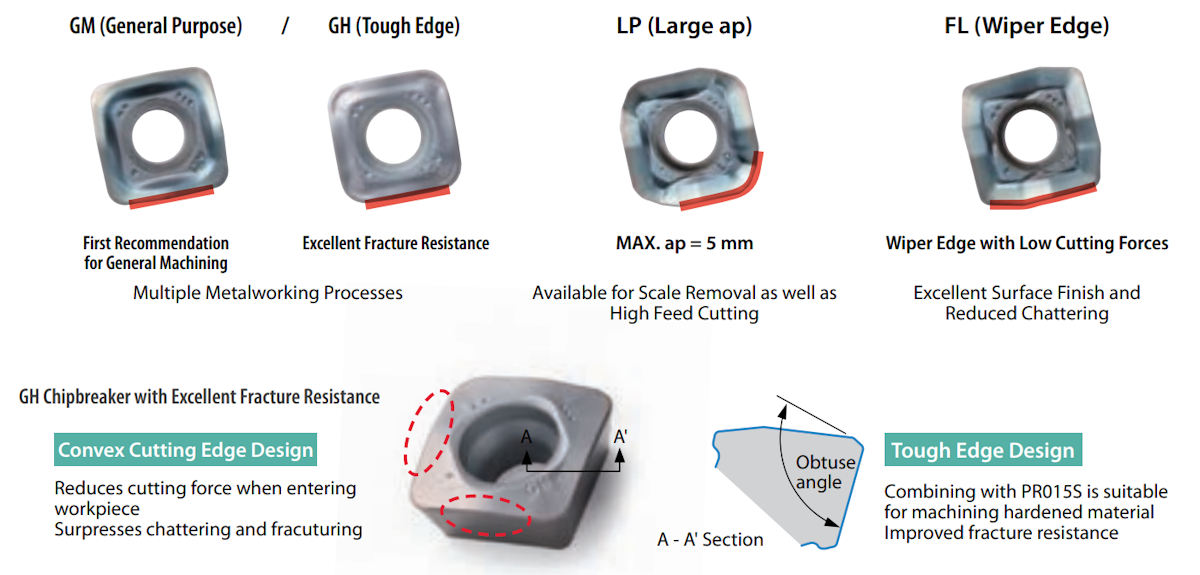

Low Cutting Force design is resistant to chattering and achieves high efficiency machining

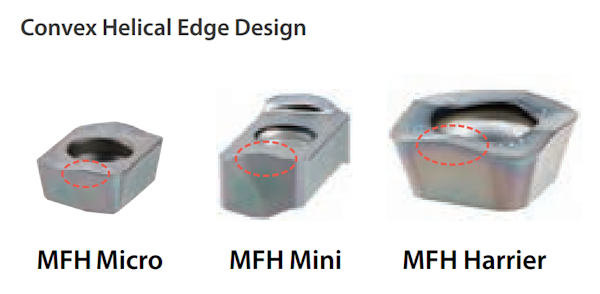

Strong resistance to chatter enables stable machining. The unique 3D convex cutting edge suppresses impact upon workpiece contact.

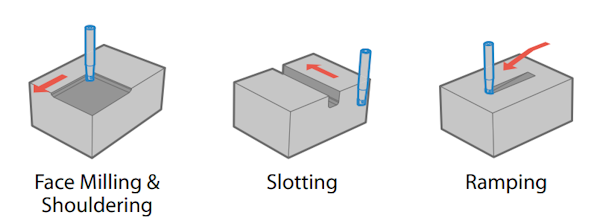

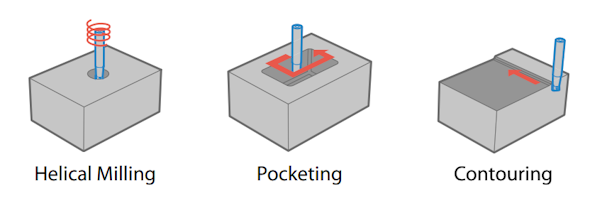

Supports a wide variety of machining applications.

MFH Micro: Ultra-small diameter High feed cutter (cutter diameter φ8 – φ16)

Low Cutting Force and resistant to chattering enables highly efficient machining.

Maximum Depth of Cut of 0.5 mm. The wide cutting area allows for stable high-feed machining.

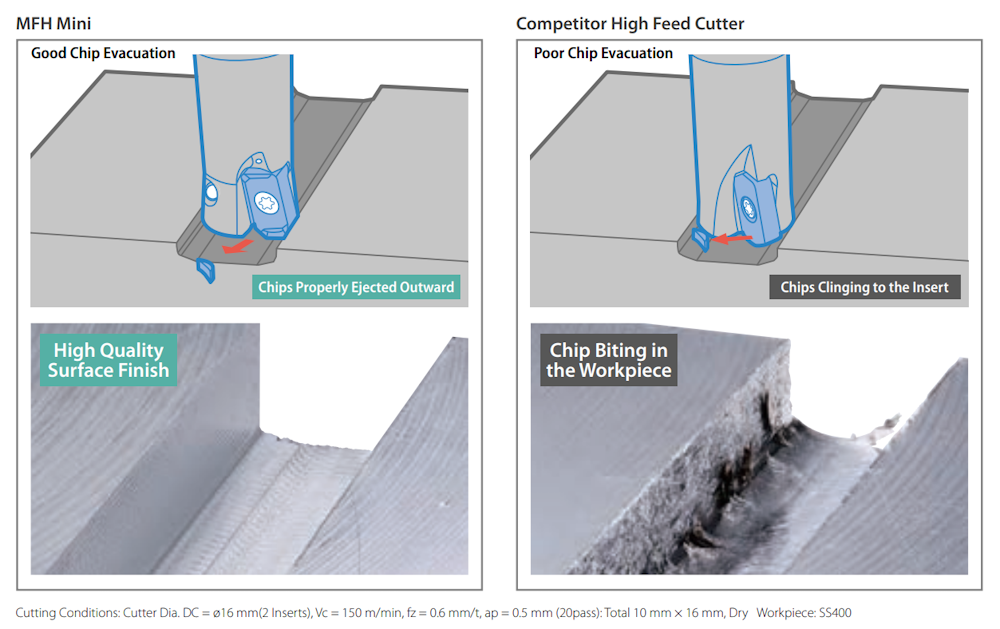

MFH Mini: Small diameter High feed cutter (cutter diameter φ16 – φ50)

Economical with double-sided 4-corner design. Small diameter wiht fine pitch design realizes high efficiency and high-feed machining.

Suppresses chip recutting with its 3D convex cutting edge. Excellent chip evacuation.

MFH Harrier: High-efficiency, High feed cutter (cutter diameter φ25 – φ160)

Achieves stable high-feed machining. : An extensive lineup that is also compatible with large depths of cut and low cutting force machining.

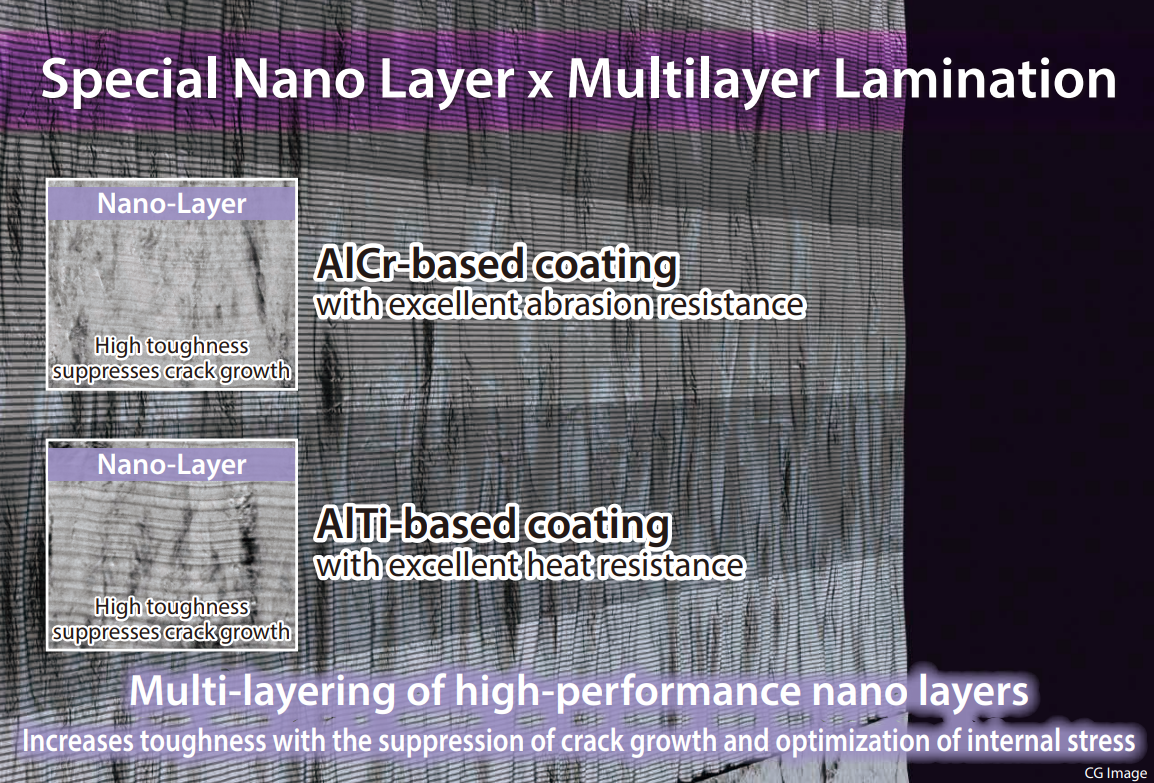

Featuring the next-generation PR18 series PVD coating for milling.

A double-layer coating technology featuring a special nano-multilayer and a multi-layer structure. MEGACOAT NANO EX achieves long tool life machining. Three insert grade Lineup: PR1825/PR1835/PR1810.

Case Study

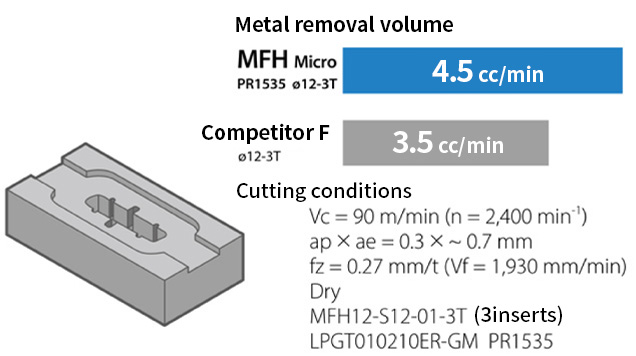

Mold SKD61 (MFH Micro)

The cutting edge condition after machining is also excellent, allowing for a tool life improvement of about two times.

(Customer evaluation)

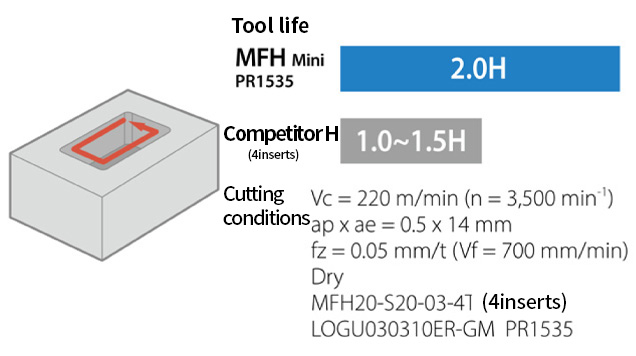

Mold parts Pre-hardened steel (MFH Mini)

(Customer evaluation)

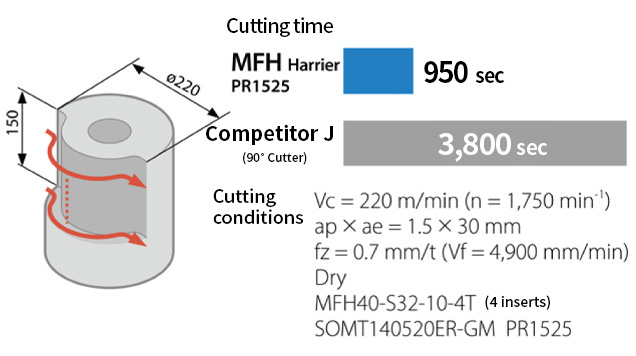

Construction machinery parts S25C (MFH Harrier)

(Customer evaluation)

Lineup

Endmill: φ8 ~ φ80

Face Mill: φ40 ~ φ160

Modular: φ8 ~ φ40

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)