- P

- M

- K

- S

MFH Boost

Features

A high-feed end mill that creates new value, compatible with large depths of cut.

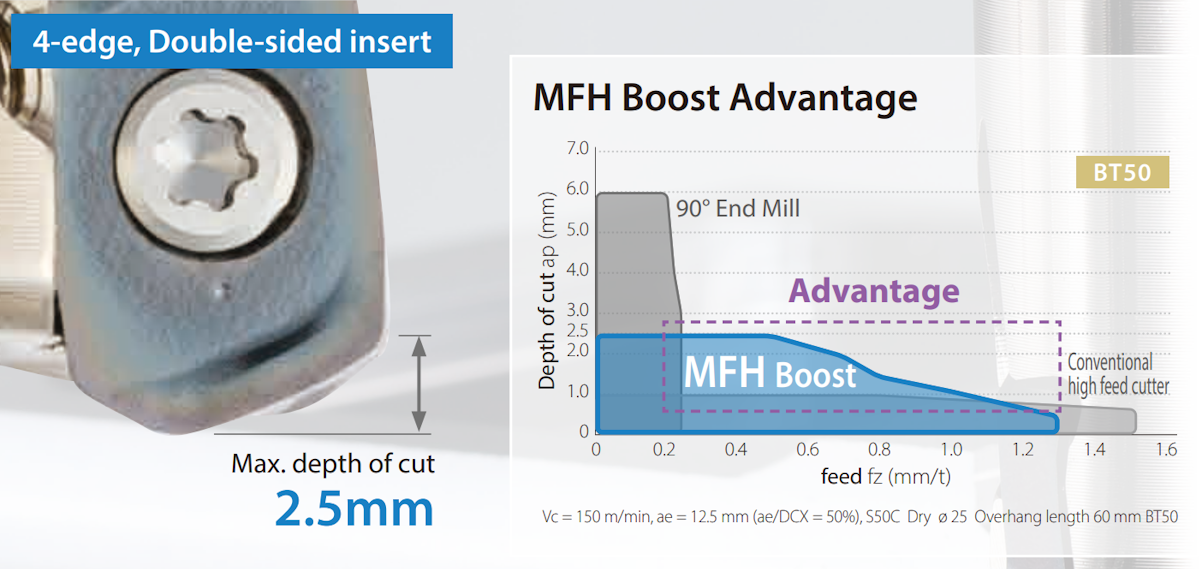

04 size small insert (double-sided, 4-corner design). Compatible with machining diameters from φ22 and a maximum depth of cut of 2.5 mm.

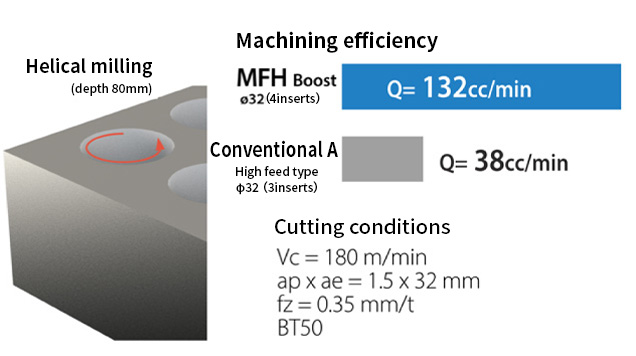

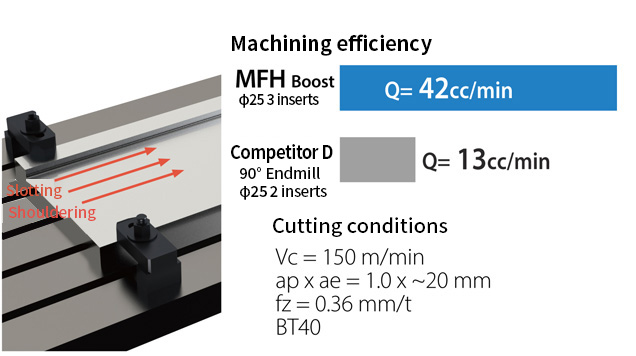

Enables higher efficiency for 3 dimensional machining, such as helical milling and ramping, as well as for roughing of shouldering and slotting.

Excels in a wide range of fields, including automotive parts, difficult-to-cut materials, and dies and molds. Solves challenges by adapting to various machining environments.

Excels in a wide variety of machining applications, solving challenges by adapting to each environment.

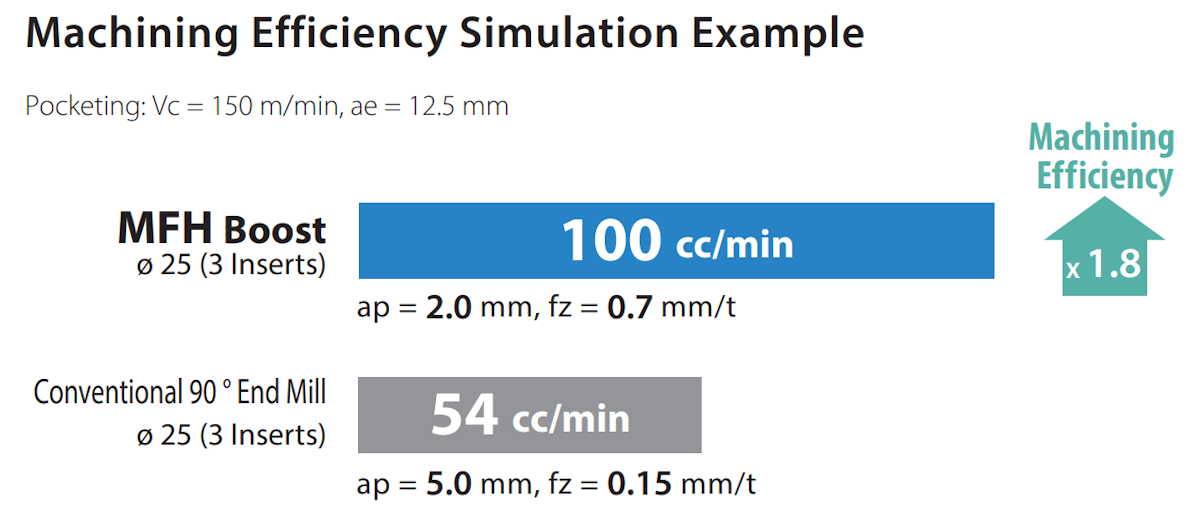

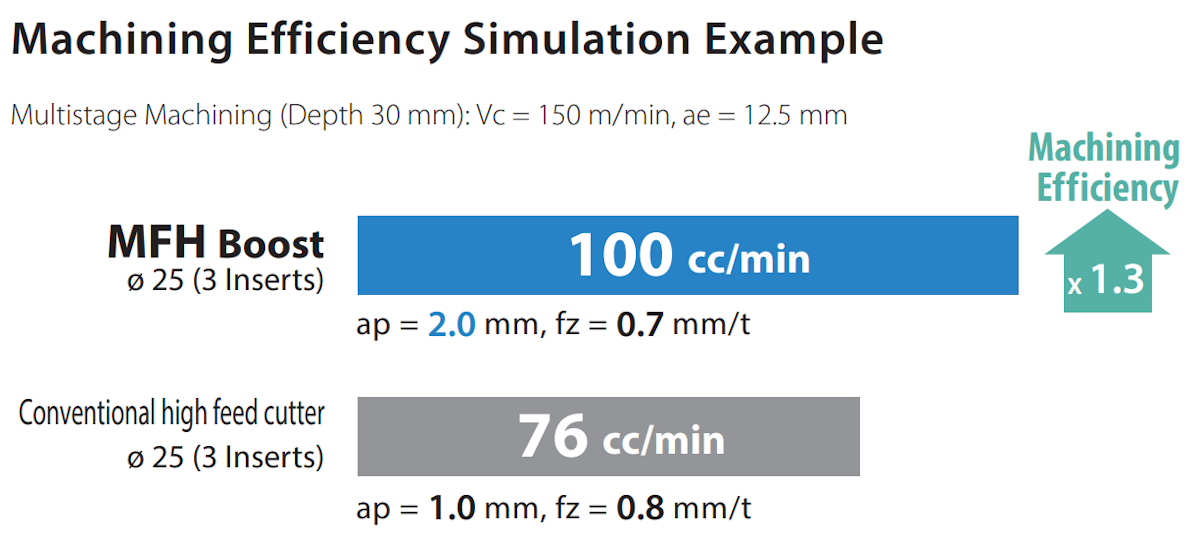

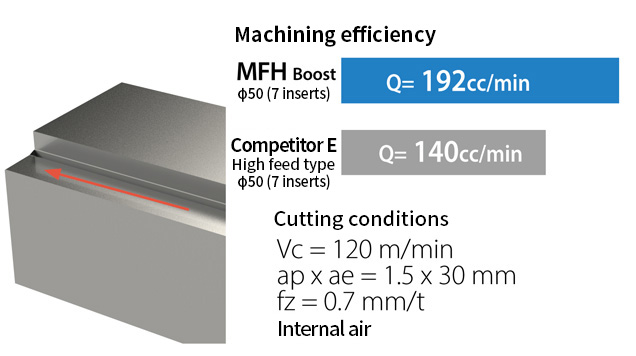

Dramatically improved machining efficiency through large depth of cut and high-feed machining.

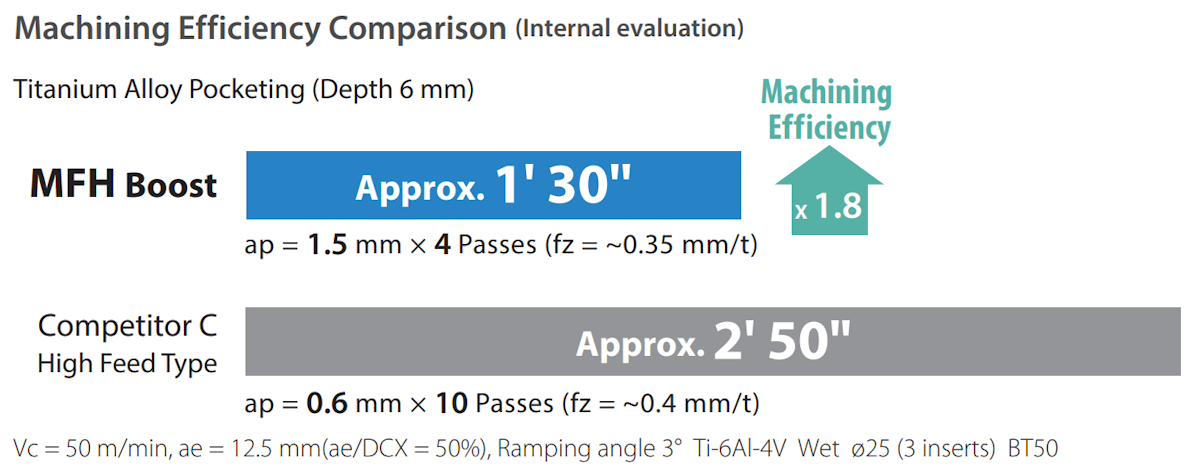

High-efficiency machining is possible even with titanium alloys and stainless steel.

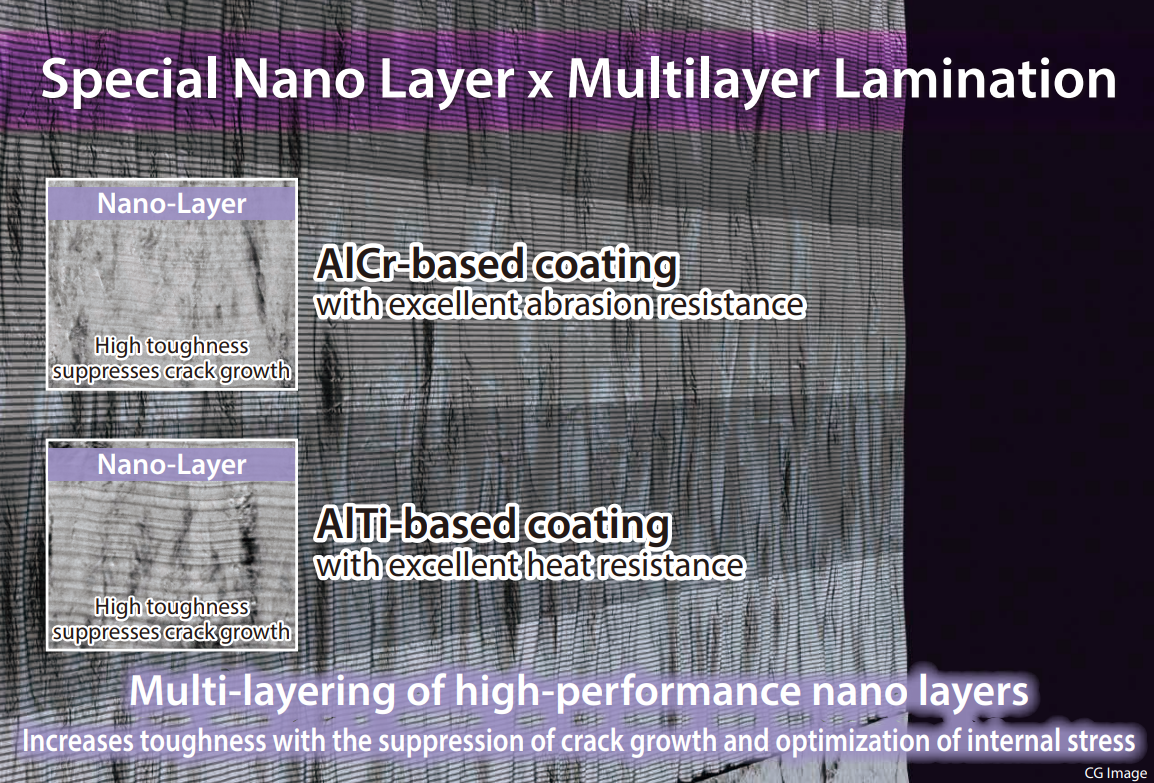

New PR18 series. Achieving significantly longer tool life

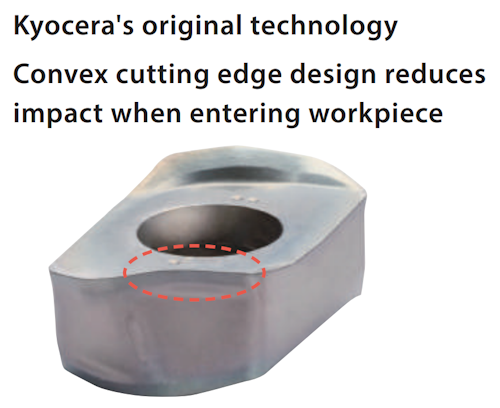

Unique insert geometry achieves high quality and long tool life

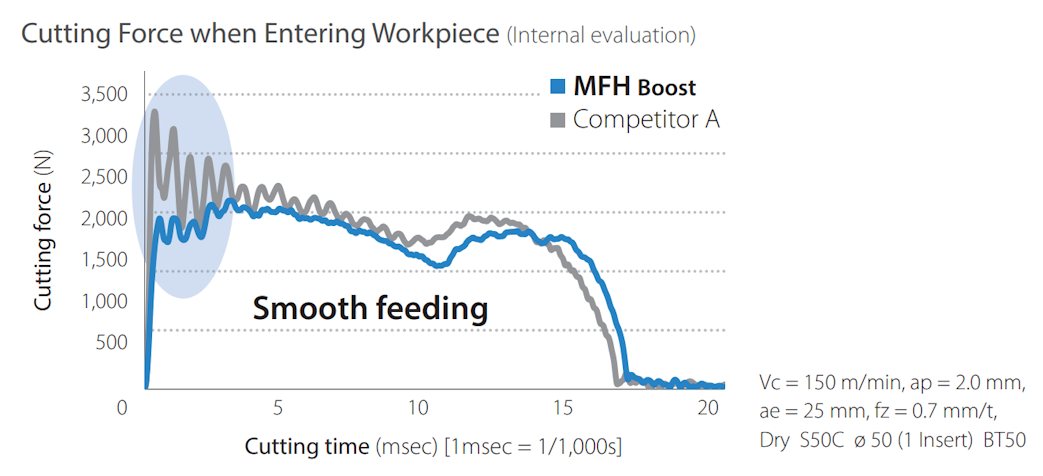

Suppresses impact upon workpiece contact with its unique 3D convex cutting edge.

Case Study

Valve parts SCM440

Industrial parts S50C

Mold parts Pre-hardened steel

Lineup

Endmill: φ22 ~ φ40

Face Mill: φ40 ~ φ80

Modular: φ22 ~ φ42

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)