- P

- M

- K

- S

- H

MFPN45

Features

Economical with double-sided 10-corner insert design

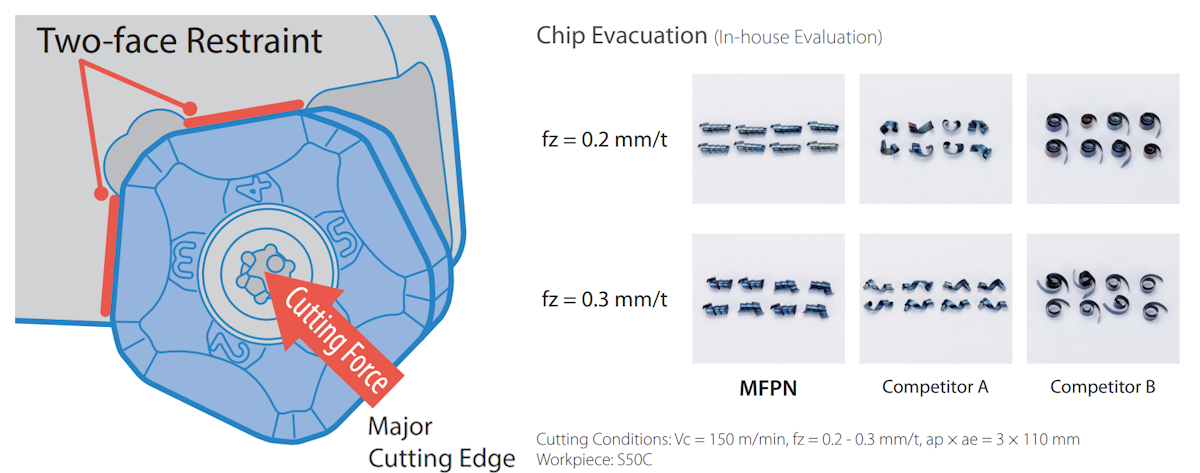

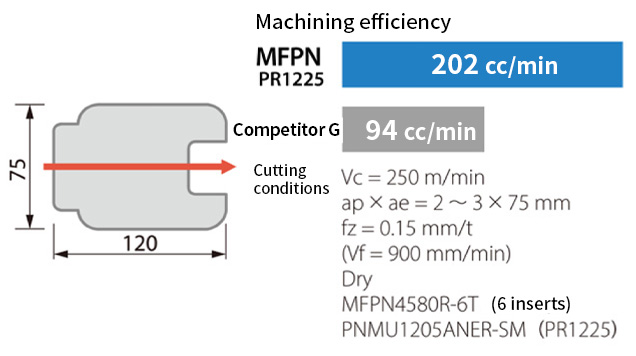

A pentagonal, double-sided insert with superior clamping force. Achieving stable high-feed machining.

Unique insert geometry for stable machining

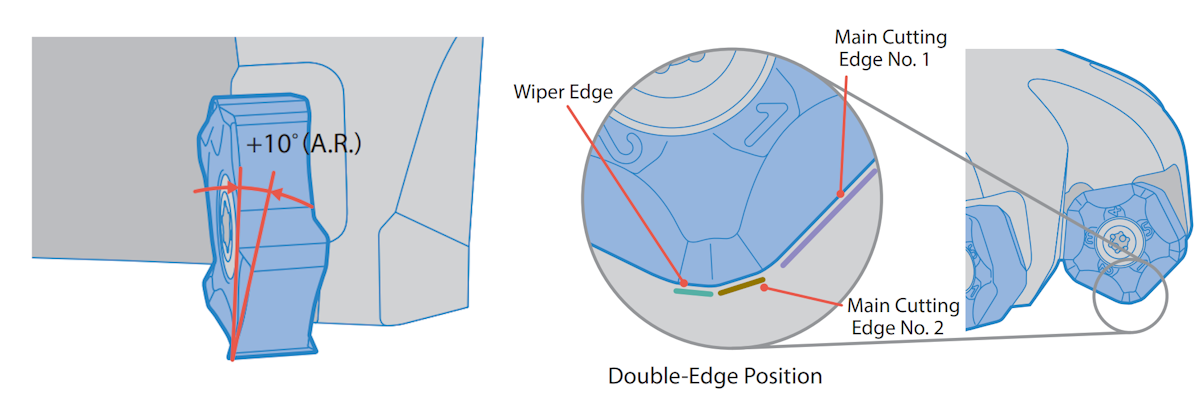

Helical cutting edge with Maximum 10° A.R. reduces cutting force and realizes excellent chatter resistance. In addition, the double edge structure reduces impact load and is resistant to fracture.

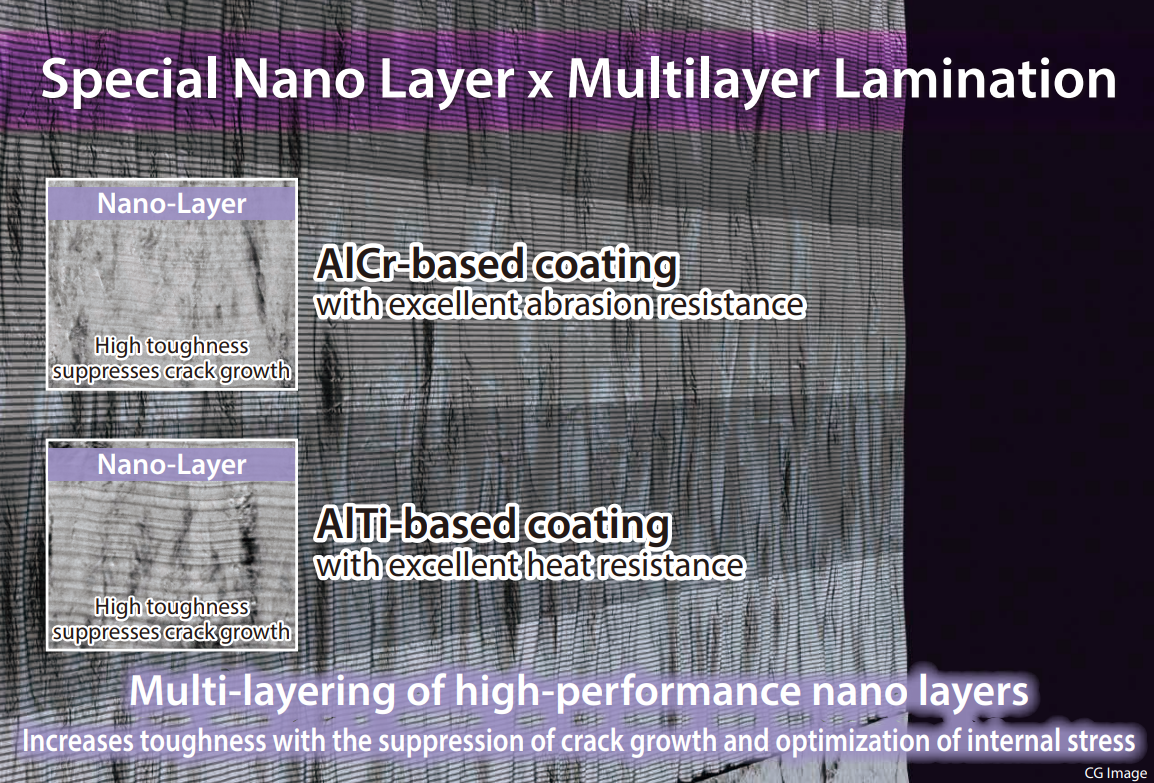

New PR18 series. Achieving significantly longer tool life

The newly developed proprietary coating MEGACOAT NANO EX achieves long tool life. "Double lamination technology" that laminates two types of special nano-layers in multiple layers further improves toughness, achieving both high levels of wear resistance and fracture resistance.

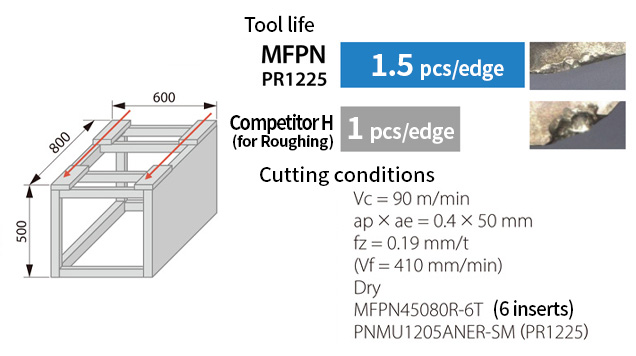

Case Study

Construction machinery parts SCM440H

(Customer evaluation)

Case: SUS304

(Customer evaluation)

Lineup

Face Mill: φ63 ~ φ315

Endmill: φ50 ~ φ80

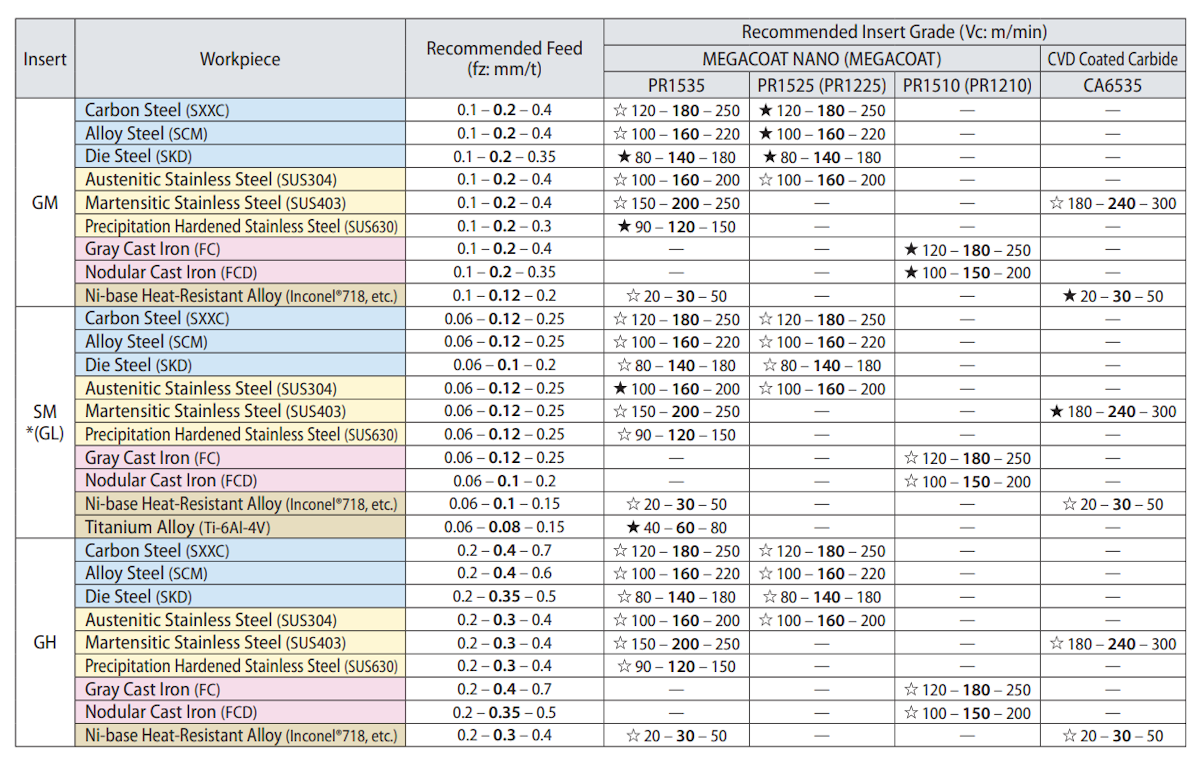

Recommended cutting conditions

The bold text in cutting conditions indicates the center value of the recommended conditions. Adjust cutting speed and feed within the range according to the actual machining conditions.

Wet machining is recommended for Ni-based heat-resistant alloys and titanium alloys.

*GL chipbreaker is recommended for machining that prioritizes surface finish. GH chipbreaker should be used with close pitch cutters at feed fz ≦ 0.4 mm/t. Not recommended for extra close pitch cutters.

For cutting conditions of new PR18 series, refer to the catalog "MFPN PR18 cutting conditions"

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)