- P

CA115P/CA125P

- External Turning

- Internal turning

- CA115P: Continuous to light interrupted machining

- CA125P: Continuous to heavy interrupted machining

Features

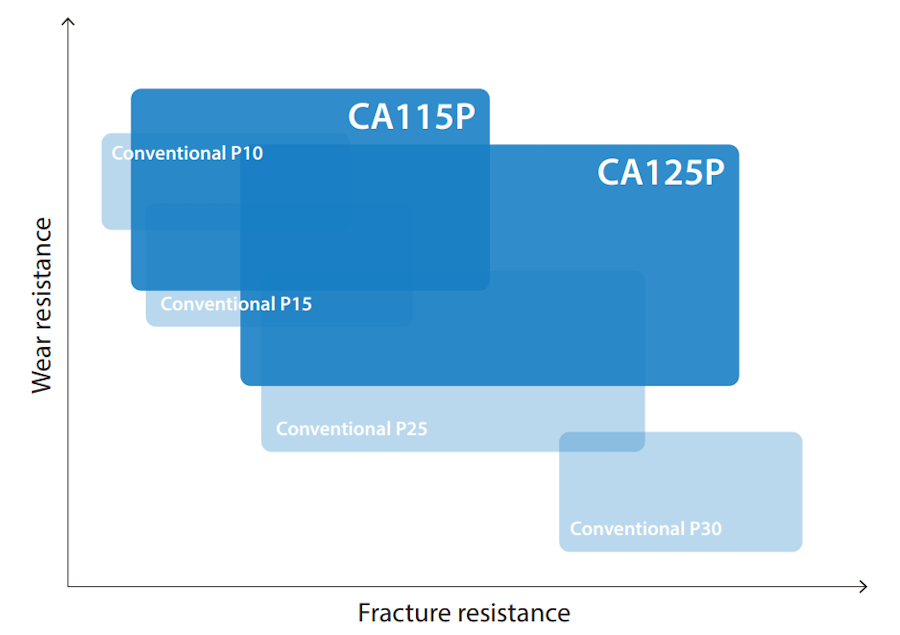

Newly Developed Proprietary Coating and Carbide Substrate, provide excellent wear and fracture resistance

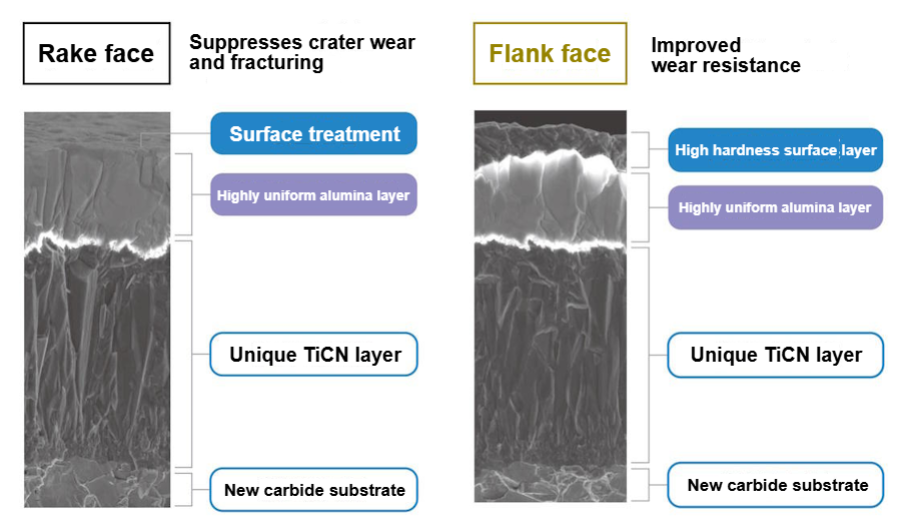

The coating properties on the rake and flank faces are optimized to achieve the high level of performance required of turning inserts. The black rake face has a highly oriented alumina layer that suppresses crater wear. Flank face has a high-hardness surface layer that suppresses abrasion. The gold surface makes it easy to identify the used corners.

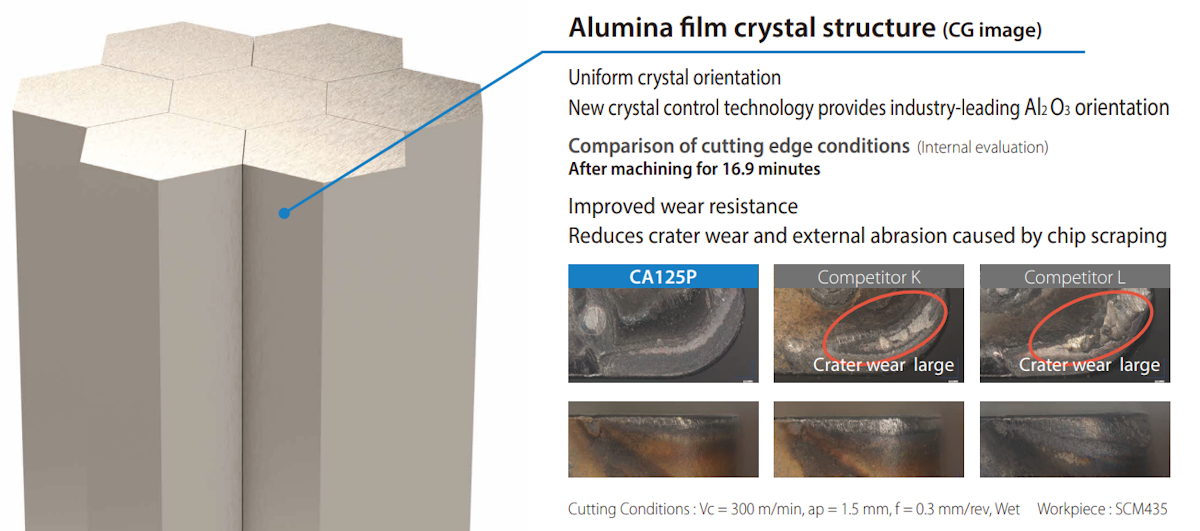

A highly oriented alumina layer suppresses crater wear

Our unique crystal control technology ensures uniform crystal orientation of the alumina layer. Excellent wear resistance due to the most uniform crystal orientation in the industry. *

*March 2023, by Kyocera research

NEW PMG chipbreaker for medium-roughing

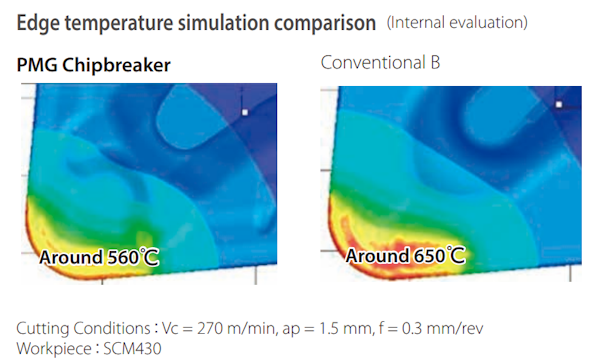

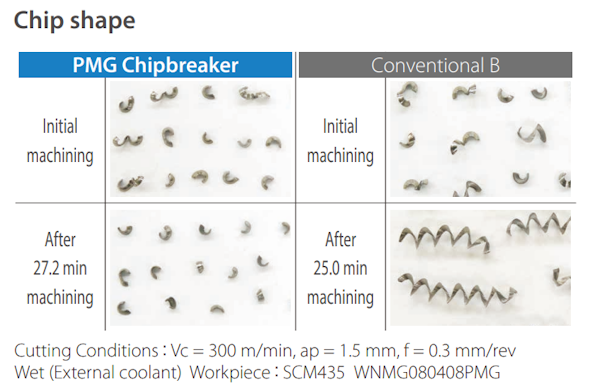

Achieves excellent chip control in a wide machining area. In addition, low-resistance design suppresses crater wear by preventing an increase in cutting edge temperature. Maintains stable chip control during prolonged machining, contributing to longer tool life.

Case Study

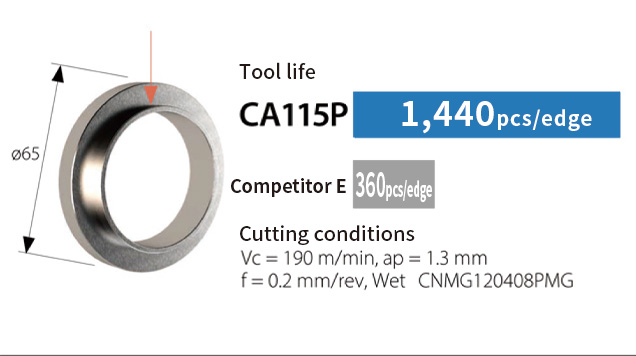

Nut S45C

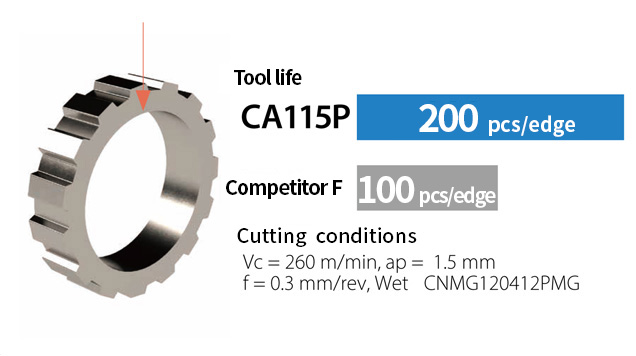

Gear S35C

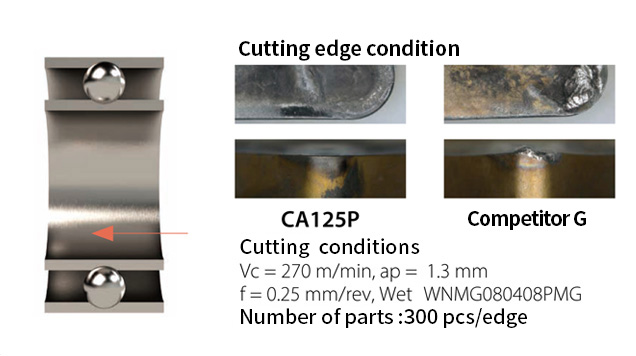

Bearing SCM415

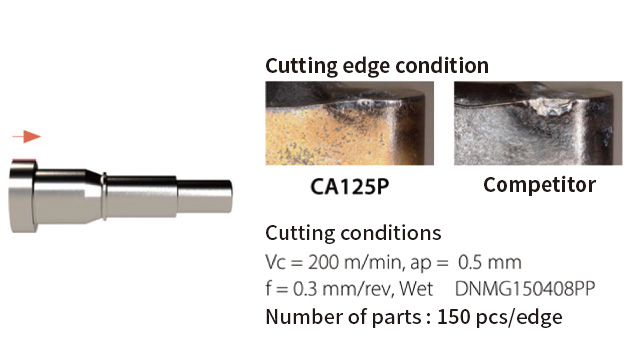

Shaft S43C

Lineup

CA115P: Continuous to light interrupted machining, high efficiency machining

CA125P: Continuous to heavy interrupted machining, Primary Recommendation

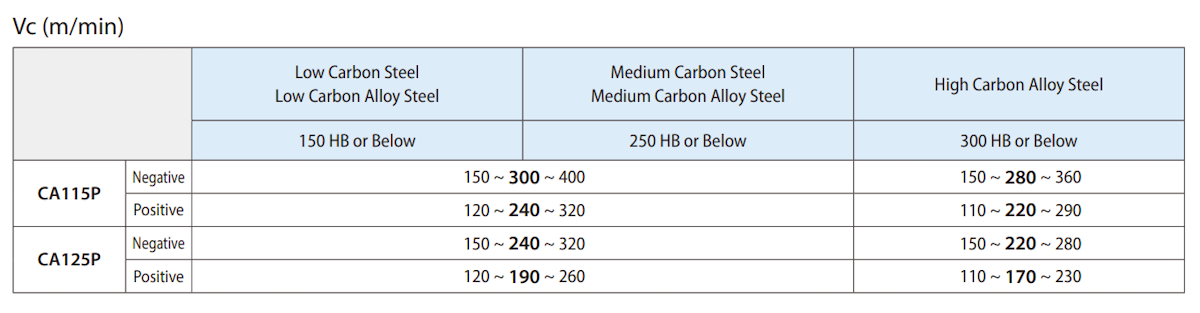

Recommended cutting conditions

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)