- P

- M

PR1725/PR1705

- External Turning

- Internal turning

Features

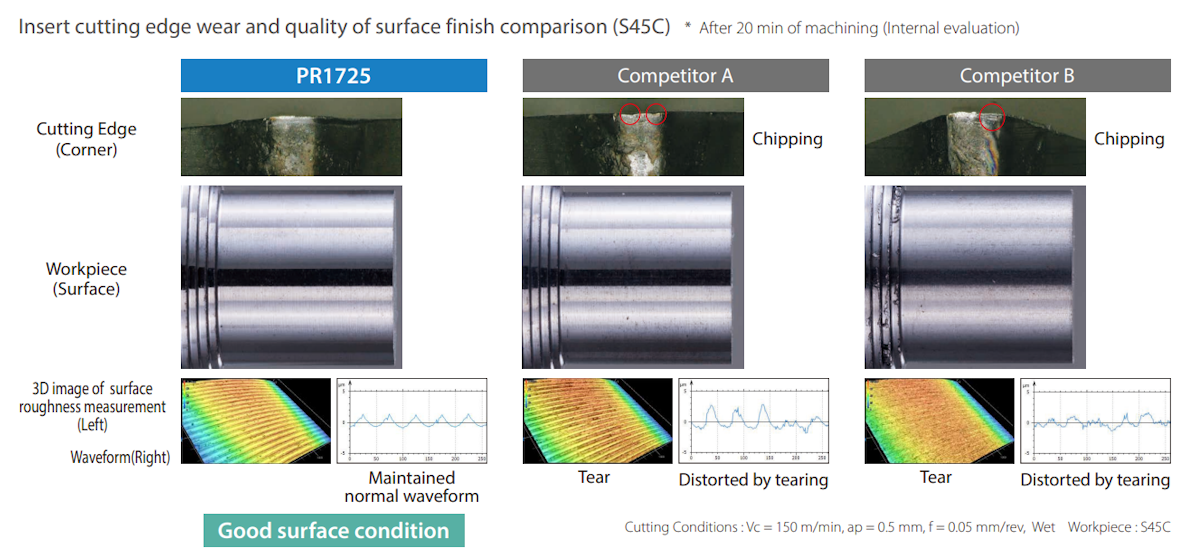

PR1725: Primary recommendation for steel machining. Achieves both long tool life and superior surface finish

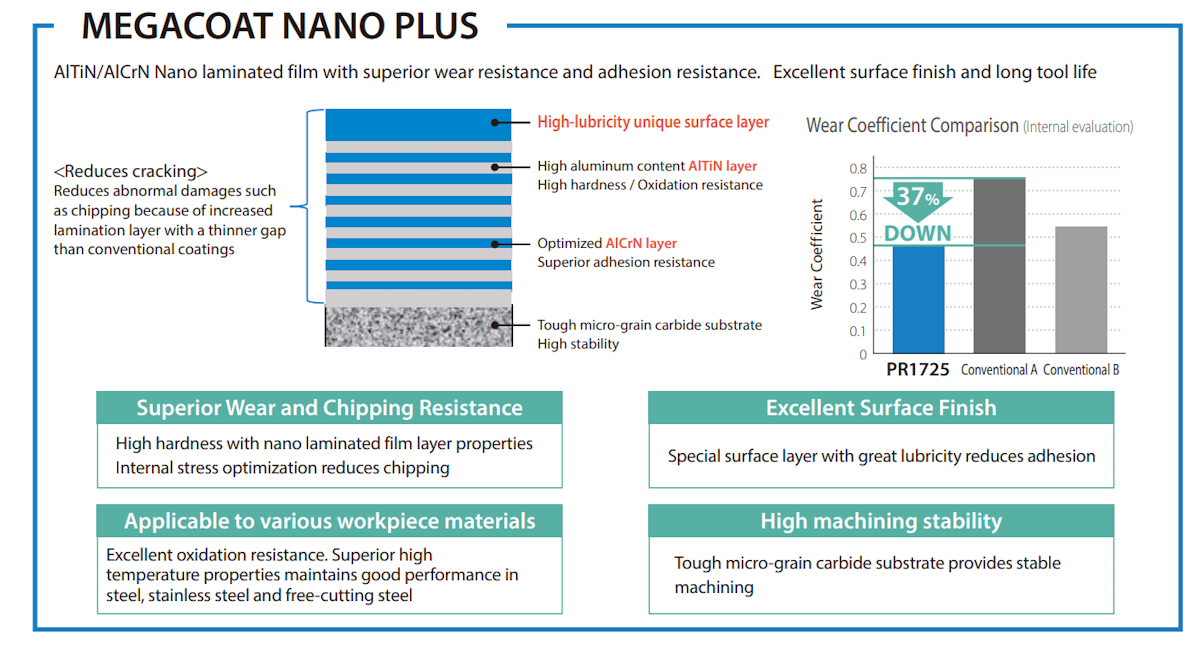

MEGACOAT NANO PLUS is used. Improved equipment operating ratio through longer tool life.

Achieved beautiful finished surfaces with suppressed tearing, which reduces quality control costs.

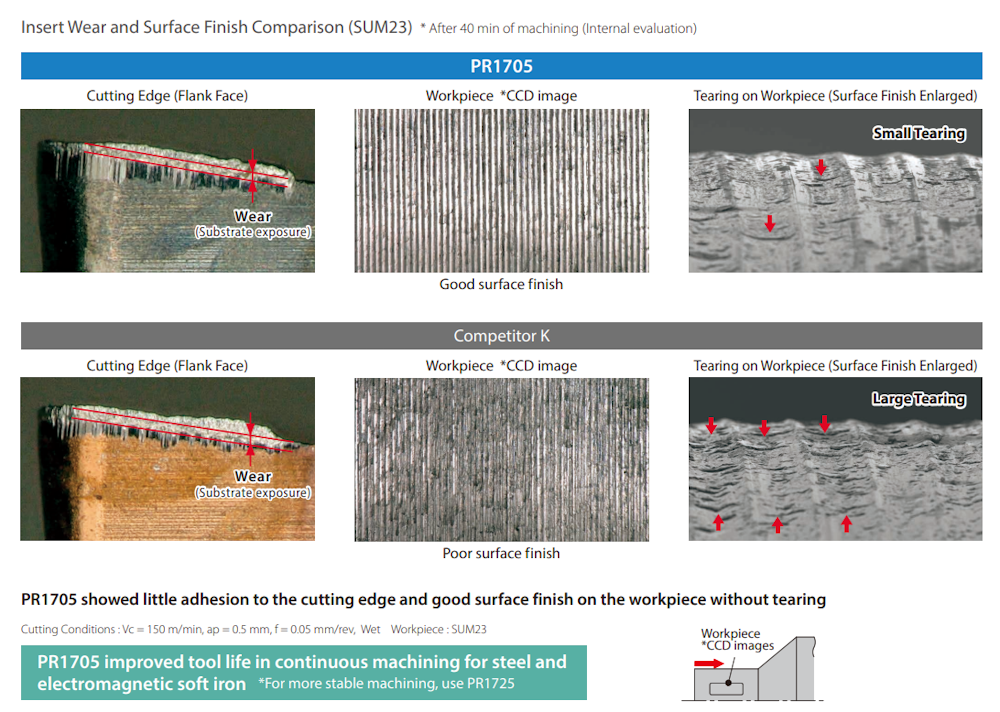

PR1705: Achieves excellent wear resistance and high precision in free-cutting steel machining

MEGACAOT NANO PLUS and high-hardness micro grain carbide substrate are used

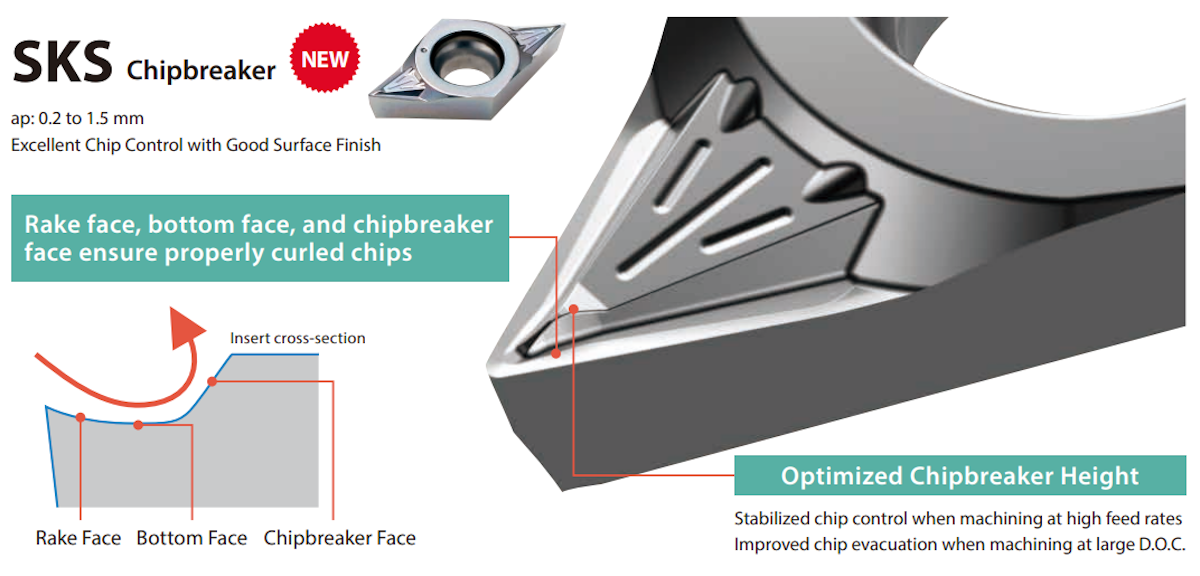

Molded sharp edge chipbreaker

A comprehensive Lineup that solves chip control problems

Combined with PR1725/PR1705, it achieves long tool life and stable machining.

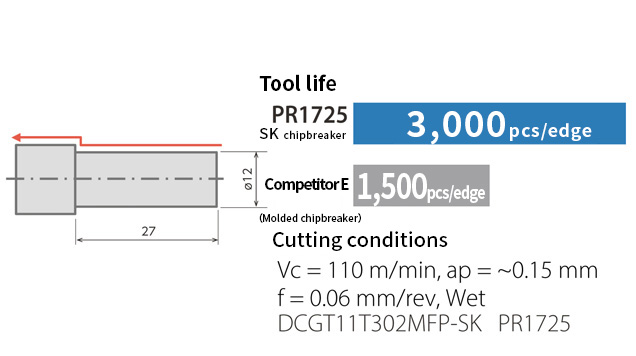

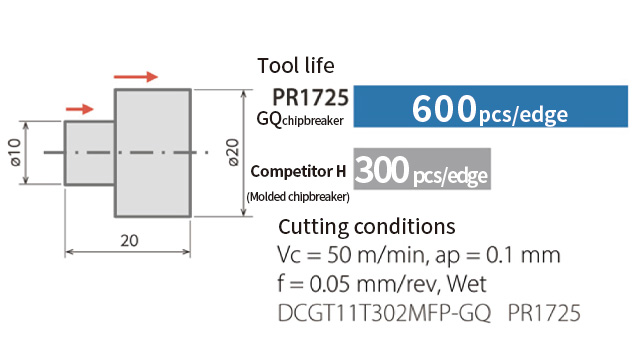

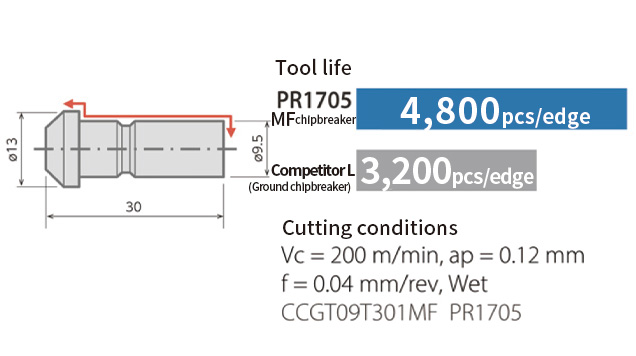

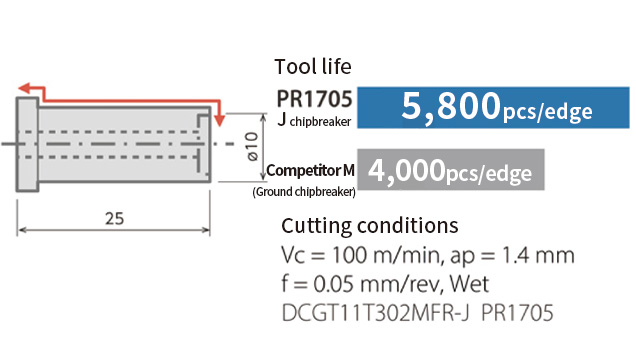

Case Study

Shaft SCM435

Shaft SUS420J2

Pin SUM24L

Shaft SUM24L

Lineup

Insert Grades

PR1725: Primary recommendation for steel machining. Effective on a variety of workpiece materials, enabling tool consolidation. Broad Application Coverage and Extensive Lineup

PR1705: Achieves excellent wear resistance and high precision in machining free-cutting steel

Molded sharp edge chipbreaker

Primary recommendation for finishing: SKS chipbreaker

Primary recommendation for semi finishing: SK breaker

Complementary chipbreakers (chip control-oriented): GQ/GF/CF chipbreakers

Recommended cutting conditions

For recommended cutting conditions, please refer to the product brochure.

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)