- M

- S

PVD coated carbide for super heat-resistant alloys machining

PR115S/PR120S

General info.

Machining video

Features

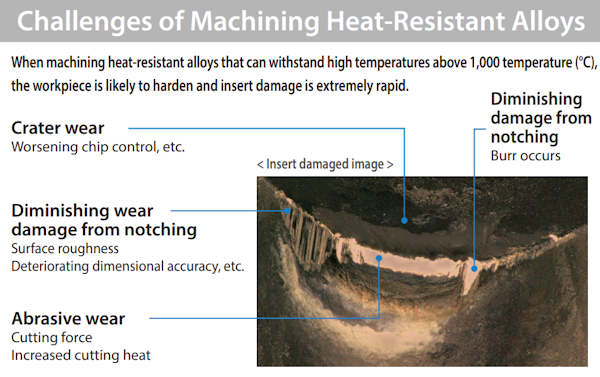

Solving Challenges with super heat-resistant alloys

Excellent heat resistance, wear resistance and stability enable long tool life and stable machining of super heat-resistant alloys.

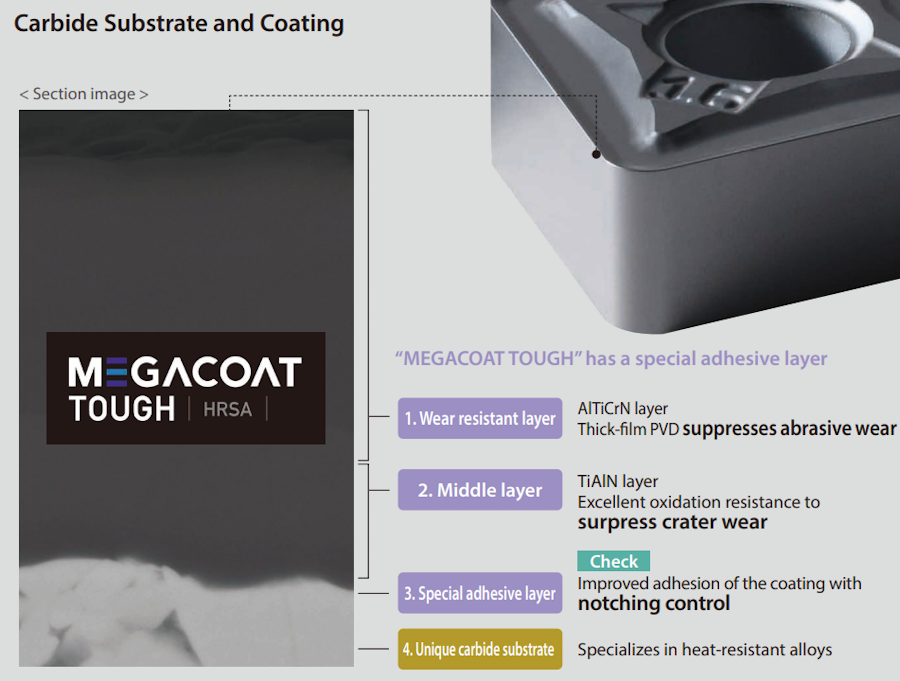

Special carbide substrate with excellent heat resistance and new coating "MEGACOAT TOUGH"

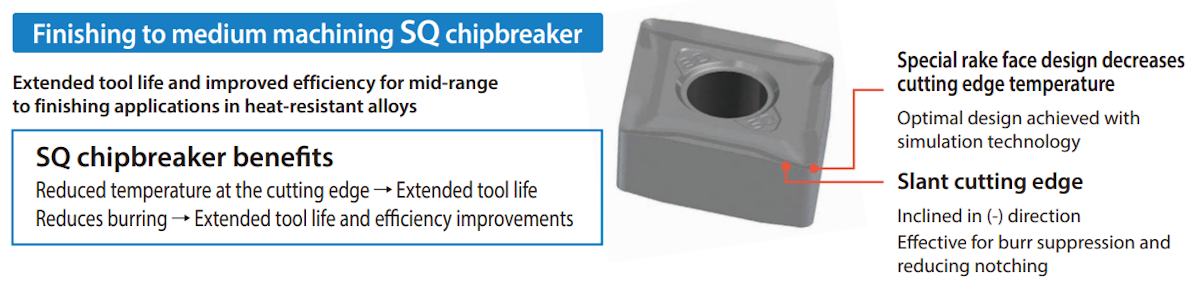

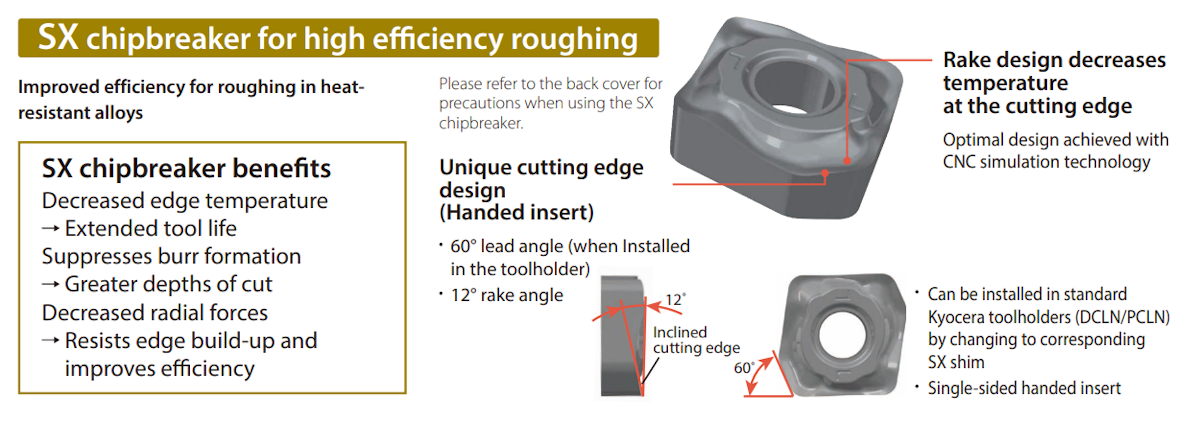

A chipbreaker designed specifically for machining super heat-resistant alloys. Low Cutting Force ensures stable machining.

Case Study

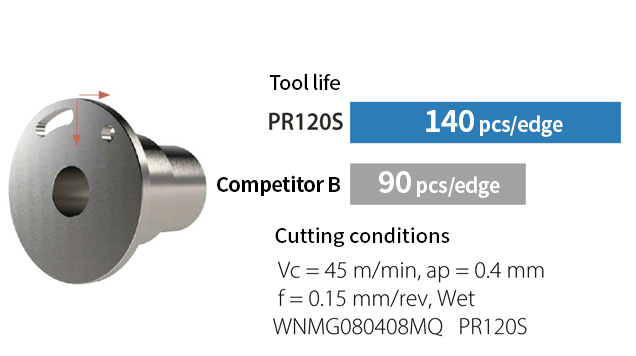

Aircraft parts Ni-based heat-resistant alloy

Achieved 1.3 times longer tool life in aircraft parts machining, which requires high heat resistance (Customer evaluation)

Agricultural machinery engine parts SUH600

Improved Tool life on all 6 corners. Stable machining achieved (Customer evaluation).

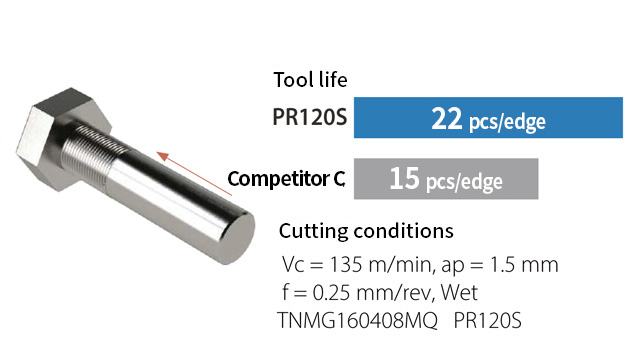

Bolt SUS304

Improved tool life in stainless steel machining (Customer evaluation)

Lineup

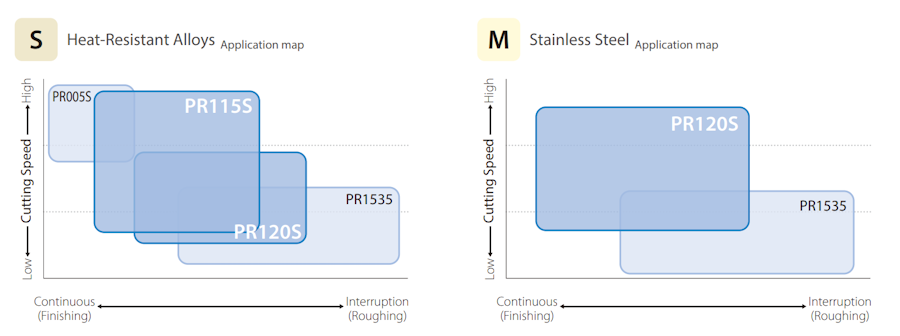

PR115S

Cover a wide range of application in difficult to cut material

Primary recommendation for continuous finishing of super heat-resistant alloys

PR120S

Achieves long tool life and stable machining in the Interrupted machining of super heat-resistant alloys

Recommended for continuous finishing to light interruption of stainless steel. Further extension Tool life is possible.

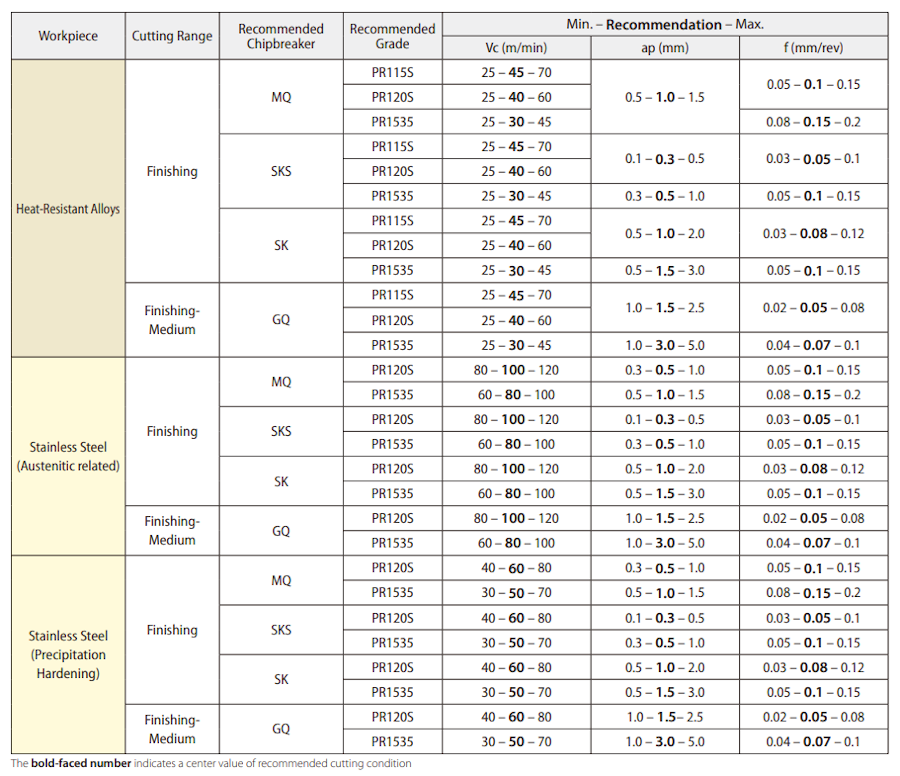

Recommended cutting conditions

![「京セラ カスタマーサポートセンター」0120-39-6369 [受付時間]9:00~12:00 13:00~17:00 ※土日祝・会社休日は受付しておりません](/prdct/tool/images/floatnav_banner01.png)